Ceiling Grid

Drywall partition

Ceiling channel

Corner Wall angle

Accessories

Steel profiles

Support customization

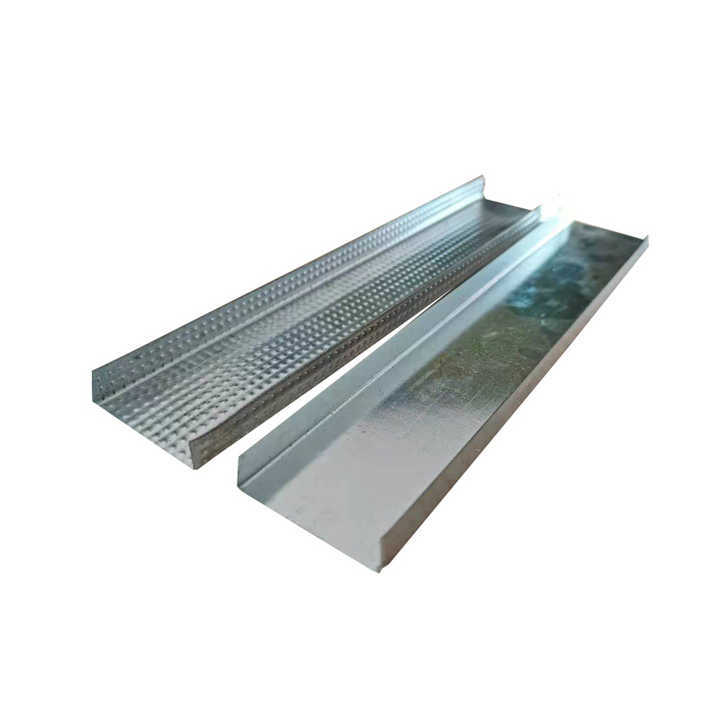

60g zinc coating metal main channel

A 60g zinc coating metal main channel refers to a type of metal channel that is coated with a layer of zinc through the process of galvanization, where the zinc coating weighs 60 grams per square meter (G60). This process enhances the channel's corrosion resistance, making it suitable for a wide range of building applications, particularly in suspended ceilings and drywall partitions.

Here’s an overview of what the 60g zinc coating metal main channel is and its key features:

Key Features of 60g Zinc Coating Metal Main Channel:

Material:

Steel or Galvanized Steel: The channel is typically made from mild steel or carbon steel, which is then coated with a layer of zinc to protect it from corrosion.

The 60g zinc coating indicates that the layer of zinc weighs 60 grams per square meter of the steel surface, providing a sufficient level of protection against moisture, rust, and oxidation in most environments.

Function:

Main channel: This metal channel is the primary component in the framing system for suspended ceilings and drywall partitions. It provides the structure onto which the furring channels or cross tees are mounted, forming the grid that supports ceiling tiles, gypsum boards, or plasterboards.

The main channel runs perpendicular to the ceiling joists or wall studs, forming the core framework of the ceiling grid.

Zinc Coating:

The galvanized coating ensures that the channel is resistant to rust and corrosion, particularly in areas with high humidity or exposure to water, such as bathrooms, kitchens, or commercial spaces.

The 60g zinc coating is often chosen for environments that don’t experience extremely harsh or high-corrosion conditions. For more extreme environments, a higher coating weight (e.g., G90) might be used.

Strength:

Galvanized steel channels are strong and durable, providing robust support for ceiling panels or drywall installations. The steel itself gives the channel the ability to bear weight and hold the ceiling system securely in place.

They are typically lightweight but strong enough to hold the weight of ceiling tiles, gypsum board, or other ceiling materials without sagging.

Sizes:

The main channel typically comes in standard sizes, with common heights being 38mm, 50mm, 75mm, or 100mm, and widths ranging from 20mm to 40mm.

Lengths can range from 2.4 meters (8 feet) to 4 meters (13 feet), and sometimes custom lengths are available for specific projects.

Durability:

The zinc coating increases the longevity of the channel, ensuring that it maintains its strength and appearance over time, even in humid or moist environments.

The galvanized steel provides protection against wear and tear, making it suitable for long-term use in ceiling and partition installations.

Uses of 60g Zinc Coating Metal Main Channel:

Suspended Ceiling Systems:

The main channel is a critical part of the suspended ceiling system. It forms the primary framework for supporting ceiling tiles or gypsum boards.

It is mounted onto the ceiling structure (e.g., beams or joists) and is used to create a grid system that holds furring channels or cross tees, which are then used to secure the ceiling panels.

Drywall Partition Framing:

In drywall partition walls, main channels are used as part of the structural framework to attach drywall panels to. The channels are spaced apart and provide a stable and level base for attaching the vertical studs and the drywall sheets.

Acoustic Ceiling Systems:

In soundproofing or acoustic ceiling systems, main channels made from galvanized steel help reduce noise transmission. They are often used in environments such as offices, schools, hospitals, and theaters, where noise control is important.

Concealed Ceiling Systems:

The main channel is part of concealed ceiling systems, where the framework is hidden behind the ceiling panels. This creates a smooth, uninterrupted ceiling surface, typically used in modern and clean designs.

Commercial and Residential Construction:

The main channel is used in both commercial and residential ceiling installations, including offices, shopping malls, homes, and more.

Advantages of 60g Zinc Coating Metal Main Channel:

Corrosion Resistance:

The 60g zinc coating offers effective protection against rust and corrosion, making it ideal for installations in areas with high humidity, such as kitchens, bathrooms, or commercial environments exposed to moisture.

Strength and Durability:

The metal channels are durable and provide strong support for heavy ceiling materials, ensuring the system remains intact over time without sagging or damage.

Cost-Effective:

Galvanized steel is generally more affordable than other materials like stainless steel, providing a cost-effective solution for building and ceiling systems while offering corrosion protection.

Ease of Installation:

The main channel is designed to be easy to install with standard suspension systems, allowing for quicker and more efficient installation of ceiling grids and drywall framing.

Low Maintenance:

Due to the zinc coating, these channels require little maintenance. The coating provides long-term protection, reducing the need for frequent repairs or replacements.

Aesthetic Flexibility:

The galvanized steel offers a clean, modern look for ceiling and partition systems. In some cases, it can even be painted for additional aesthetic options.

Installation Process:

Preparation:

Measure and mark the locations for main channels on the ceiling structure or wall.

Ensure that the suspension wires or hanger rods are securely fixed to the ceiling beams or joists.

Main Channel Installation:

Attach the main channels to the ceiling structure, ensuring they are level and securely fastened using appropriate hardware.

The channels should be spaced at intervals, typically 1200mm apart, depending on the load requirements and the type of ceiling material used.

Furring Channel Installation:

After the main channels are installed, furring channels or cross tees are fixed perpendicular to them to create the grid structure.

Fixing Ceiling Panels:

Once the grid is in place, ceiling panels (e.g., gypsum board or tiles) can be attached to the channels using screws or clips.

Finishing:

Complete the ceiling or partition system by securing edges, applying finishing compounds, and smoothing out any seams or joints.

Conclusion:

The 60g zinc coating metal main channel is a highly effective and durable component used in the construction of suspended ceiling systems and drywall partitions. Its corrosion-resistant properties, strength, and ease of installation make it an ideal choice for a wide range of construction projects, both in commercial and residential settings. The galvanized coating provides long-lasting protection, ensuring the stability and longevity of ceiling and partition systems.

Selection Guide for Ceiling Channel Materials: A Comparison of Light Steel vs. Aluminum in Terms of L

In ceiling construction projects, ceiling channels serve as the critical framework supporting the ceiling surface layer, and their material selection directly impacts the project's quality and service life.

2025-07-06

Designing with Corner Wall Angles: Enhancing Room Aesthetics with Finishing Touches

Introduction In the world of interior design, even the smallest details can make a significant impact on the overall aesthetic of a room. One often overlooked area is the corner wall angles. These seemingly insignificant junctions between w

2025-07-03

Commercial-Grade Corner Wall Angles for Heavy-Duty Construction Projects

In heavy-duty construction projects such as industrial plants, large commercial complexes, and transportation hubs, corners are critical parts of the building structure that constantly face severe challenges. Frequent collisions from heavy equipment and e

2025-06-30

DIY Corner Wall Angle Finishing and Professional Results

In home decoration, DIY corner wall treatments have gained immense popularity among homeowners striving to elevate the quality of their living spaces. Corners are susceptible to damage and highly noticeable, so the way they are handled directly influences

2025-06-27