Ceiling Grid

Drywall partition

Ceiling channel

Corner Wall angle

Accessories

Steel profiles

Support customization

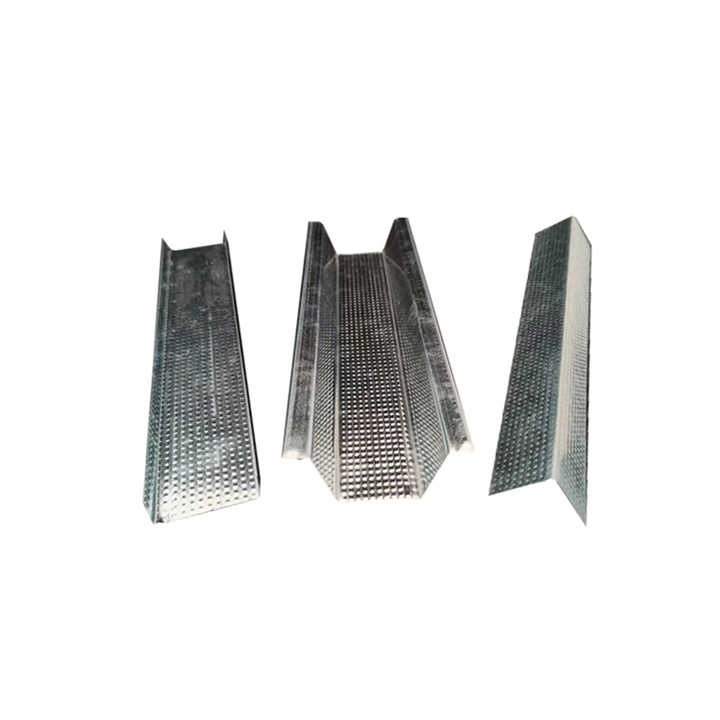

Galvanized steel 60g zinc coating Furring channel

A Galvanized Steel Furring Channel with 60g Zinc Coating is a metal framing component used in ceiling and wall systems, designed to support materials such as gypsum boards, drywall, or acoustic panels. The key characteristic of this furring channel is its zinc coating, which provides corrosion resistance and extends its durability in various building applications.

Key Features of Galvanized Steel 60g Zinc Coating Furring Channel:

Material:

Steel: The furring channel is made of galvanized steel, offering both strength and lightweight characteristics, making it easy to handle and install.

Zinc Coating: The channel has a 60g zinc coating (measured in grams of zinc per square meter), which protects the steel from rust and corrosion. This makes it particularly suitable for environments where moisture levels can be high, such as in kitchens, bathrooms, or commercial buildings with high humidity.

Zinc Coating:

The 60g zinc coating means that each square meter of the furring channel is coated with 60 grams of zinc. This level of coating is typically sufficient for moderate exposure to corrosive environments and offers a balanced cost-to-performance ratio for most residential, commercial, and industrial projects.

Shape:

The furring channel usually comes in a C-shaped or U-shaped profile, depending on the design and load requirements. The channel provides support for ceiling tiles, drywall, plasterboard, or acoustic panels.

Size:

Width: Typically ranges from 25mm to 75mm.

Thickness: Ranges from 0.6mm to 1.2mm.

Length: Available in lengths ranging from 2 meters to 6 meters, or custom lengths based on specific requirements.

The width and thickness of the furring channels may vary depending on the project’s needs. Common sizes include:

Surface Finish:

The galvanized finish ensures the furring channels are resistant to corrosion and rust, especially in environments exposed to moisture or damp conditions.

Applications of Galvanized Steel 60g Zinc Coating Furring Channel:

Suspended Ceilings:

Ceiling Grid Systems: These furring channels are commonly used in suspended ceiling systems, where they form the grid that holds the ceiling panels in place. The channel is attached to the main suspension system and supports the weight of the ceiling tiles or drywall.

Drywall and Plasterboard:

Wall Framing: In drywall or plasterboard systems, galvanized furring channels provide a stable framework for attaching the wall materials. These systems are commonly used in office partitions, residential walls, and commercial interiors.

Acoustic Ceiling Systems:

These channels are also used in the construction of acoustic ceilings, where they support soundproof panels designed to reduce noise in environments such as schools, offices, and hospitals.

Industrial Applications:

In industrial buildings or warehouses, galvanized steel furring channels are used for creating suspended ceilings that may hold not only ceiling panels but also utilities like lighting fixtures, HVAC ducts, or wiring.

Facade Systems:

Furring channels can be used to support materials in facade systems or exterior cladding, offering a robust framework for materials such as cement boards, metal panels, or wooden slats.

Advantages of Galvanized Steel 60g Zinc Coating Furring Channel:

Corrosion Resistance:

The 60g zinc coating helps protect the steel from rust and corrosion, particularly in moderate exposure to moisture or humid environments. This makes it ideal for use in places like bathrooms, kitchens, and commercial buildings.

Cost-Effective:

Compared to channels with higher zinc coatings, the 60g coating provides a cost-effective solution, offering good corrosion protection at a reasonable price. It’s well-suited for typical construction projects with moderate environmental exposure.

Strength and Stability:

Steel is a strong and stable material that offers the load-bearing capacity required for supporting ceiling tiles, drywall, or acoustic panels. This ensures that the ceiling system remains secure and stable over time.

Durability:

The combination of galvanized steel and zinc coating ensures that the furring channels will withstand the test of time, even in environments where moisture exposure might be a concern.

Ease of Installation:

These channels are easy to install and are lightweight compared to heavier framing materials, which makes them a popular choice for contractors and builders. The channels can be easily fixed using screws, clips, or hangers.

Versatility:

Galvanized steel furring channels with 60g zinc coating are versatile and can be used in a variety of applications, from suspended ceilings to partition walls and acoustic systems, as well as industrial uses.

Installation Process:

Measurement and Marking:

First, measure and mark the ceiling or wall area where the furring channels will be installed. Ensure the proper spacing (typically 600mm apart) for the furring channels.

Suspension (for ceilings):

For suspended ceiling systems, suspension wires or brackets are attached to the main ceiling structure. The furring channels are then hung from these suspension points.

Attaching the Channels:

Once the channels are suspended, they are secured to the ceiling grid system or attached directly to wall framing, depending on the application.

Install Ceiling or Wall Panels:

After the furring channels are in place, ceiling tiles, drywall, or acoustic panels are attached to the channels, ensuring they are securely fixed.

Final Adjustments:

Once all the panels are installed, check the alignment and level of the system, and make any necessary adjustments to ensure a flat and even ceiling or wall surface.

Conclusion:

A Galvanized Steel Furring Channel with a 60g Zinc Coating is a reliable and cost-effective solution for suspended ceilings, drywall partitions, and acoustic systems. Its corrosion resistance, strength, and durability make it ideal for use in environments with moderate moisture exposure. Whether for residential, commercial, or industrial applications, these furring channels provide a secure framework for a wide range of ceiling and wall systems.

The Advantages and Applications of Light Steel Keel: Why It Has Become the Preferred Material in Mode

In the modern construction industry, light steel keel has gradually become an indispensable building material. With its outstanding performance and diverse applications, light steel keel has become the material of choice for many building projects. So, wh

2025-03-08

Advantages and Applications of Drywall partitions: Easily Create Multifunctional Spaces

In modern architecture and interior design, efficient space division and utilization are key. Drywall partitions, with their unique advantages, have become the material of choice for an increasing number of construction and renovation projects. Whether in

2025-03-05

The Future of Light Steel Walls: Technological Innovation and Market Prospects

In the construction industry, light steel walls have gradually become an important choice in modern buildings due to their superior performance and environmentally friendly characteristics. With the continuous advancement of technology and changing market

2025-03-02

New Trends in Building Energy Efficiency: How Light Steel Walls Contribute to Green Environmental Pro

As global climate change and environmental issues become increasingly severe, energy efficiency and environmental protection have become critical topics in modern societal development. Whether it's controlling energy consumption or reducing greenhouse gas

2025-02-27