Ceiling Grid

Drywall partition

Ceiling channel

Corner Wall angle

Accessories

Steel profiles

Support customization

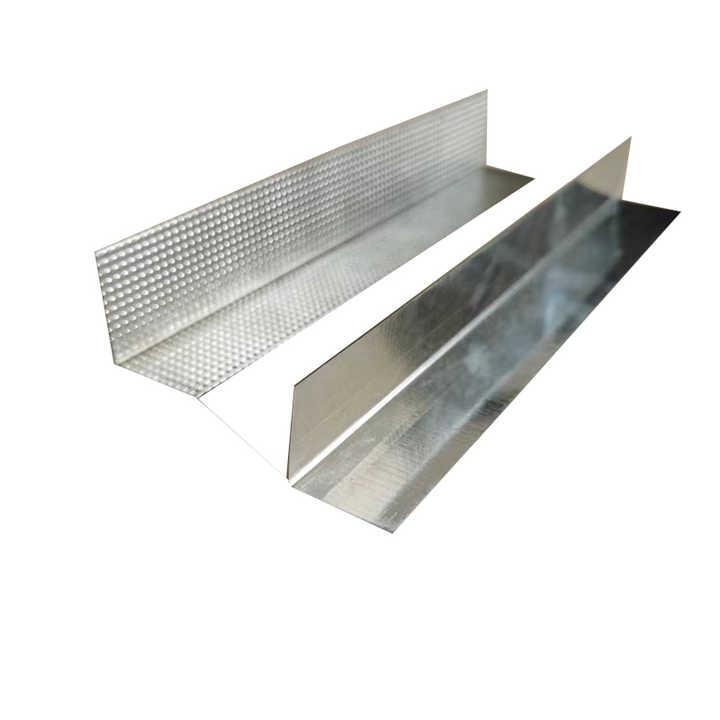

Galvanized steel angle

Galvanized Steel Angle is a type of structural steel with a specific "L" shape, often used in construction and manufacturing. It is hot-dip galvanized to provide superior corrosion resistance, making it ideal for outdoor and high-humidity environments where protection against rust and deterioration is important.

Key Features of Galvanized Steel Angle:

Material:

Galvanized Steel: The steel is coated with a layer of zinc to prevent rust and corrosion, a process called galvanization. This gives the angle iron its characteristic silver-gray appearance and extends its lifespan.

Durability: Galvanized steel is known for its long-term strength and ability to withstand harsh environments, such as exposure to moisture, chemicals, and high temperatures.

Shape and Dimensions:

L-Shape: The steel is formed into an L-shaped profile, with two perpendicular legs that typically have equal or unequal lengths.

Dimensions: The legs (sides) of the angle can vary in length, typically ranging from 25mm to 200mm or more, depending on the application. Common thicknesses range from 3mm to 12mm.

Lengths: Galvanized steel angles are usually available in lengths of 6 meters, 9 meters, or custom lengths based on the project requirements.

Finish:

Hot-Dip Galvanized: The steel is immersed in molten zinc, forming a protective coating that enhances resistance to corrosion, especially in outdoor or exposed conditions.

Strength:

Galvanized steel angles are strong and can carry significant loads, making them suitable for structural purposes in construction.

Applications of Galvanized Steel Angle:

Construction:

Support Frames: Galvanized steel angles are widely used in the construction of support frames for buildings, bridges, and other structures. They provide a strong and stable framework for various elements like walls, ceilings, and roofs.

Steel Structures: Used in steel buildings and structural components like beams, columns, and braces. Their strength and corrosion resistance make them ideal for these applications.

Industrial Applications:

Racking Systems: Used to build industrial shelving, racking systems, and storage units in warehouses and factories due to their strength and durability.

Conveyor Systems: Galvanized steel angles are used in the construction of conveyor frames and other heavy-duty material handling equipment.

Exterior Use:

Fencing and Gates: Galvanized steel angles are used in fencing, gate frames, and railings for added durability and corrosion resistance.

Roofing and Cladding: They are used as structural support in roofing and cladding systems, where exposure to the elements is frequent.

Automotive and Machinery:

Frames and Supports: Galvanized steel angles are commonly used in the manufacturing of automotive frames, machinery, and equipment that require strong and durable components.

Electrical and Utility Applications:

Cable Trays and Supports: Galvanized steel angles are used for cable trays and supports in electrical installations to provide a stable and corrosion-resistant foundation for wiring and conduit.

Advantages of Galvanized Steel Angle:

Corrosion Resistance:

The zinc coating protects the steel from rust and corrosion, especially in outdoor environments, making it suitable for long-lasting installations.

Strength:

Galvanized steel angles provide high load-bearing capacity and structural integrity, making them ideal for construction and industrial uses.

Long Lifespan:

Galvanization significantly increases the lifespan of steel, ensuring that the material remains functional and resistant to the elements for many years.

Cost-Effective:

Galvanized steel is relatively cost-effective compared to other corrosion-resistant materials like stainless steel, offering good value for long-term durability.

Maintenance-Free:

Galvanized steel requires little to no maintenance due to its resistant coating, unlike non-galvanized steel, which may need periodic repainting or treatment against rust.

Versatility:

The L-shape of galvanized steel angles makes them highly versatile for a wide variety of applications, both structural and aesthetic.

Conclusion:

Galvanized steel angles are a highly durable and cost-effective choice for various construction, industrial, and manufacturing applications. The corrosion-resistant properties provided by the hot-dip galvanizing process make them especially suited for environments exposed to moisture or extreme weather. With their strength, versatility, and long lifespan, galvanized steel angles are essential components for building reliable and long-lasting structures.

The Advantages and Applications of Light Steel Keel: Why It Has Become the Preferred Material in Mode

In the modern construction industry, light steel keel has gradually become an indispensable building material. With its outstanding performance and diverse applications, light steel keel has become the material of choice for many building projects. So, wh

2025-03-08

Advantages and Applications of Drywall partitions: Easily Create Multifunctional Spaces

In modern architecture and interior design, efficient space division and utilization are key. Drywall partitions, with their unique advantages, have become the material of choice for an increasing number of construction and renovation projects. Whether in

2025-03-05

The Future of Light Steel Walls: Technological Innovation and Market Prospects

In the construction industry, light steel walls have gradually become an important choice in modern buildings due to their superior performance and environmentally friendly characteristics. With the continuous advancement of technology and changing market

2025-03-02

New Trends in Building Energy Efficiency: How Light Steel Walls Contribute to Green Environmental Pro

As global climate change and environmental issues become increasingly severe, energy efficiency and environmental protection have become critical topics in modern societal development. Whether it's controlling energy consumption or reducing greenhouse gas

2025-02-27