Ceiling Grid

Drywall partition

Ceiling channel

Corner Wall angle

Accessories

Steel profiles

Support customization

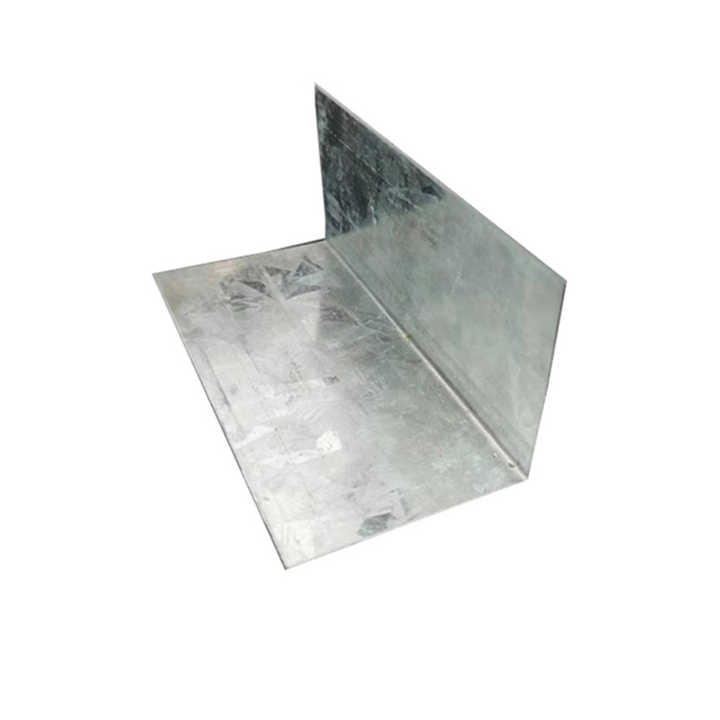

0.75x3600mm metal angle wall angle

A 0.75x3600mm metal angle wall angle is a building material commonly used in drywall and gypsum board installations. This particular metal angle is typically made from steel, galvanized steel, or another corrosion-resistant metal, and is designed to provide both structural support and aesthetic finishes at the junctions where walls meet ceilings or other walls.

Key Features of the 0.75x3600mm Metal Angle Wall Angle:

Dimensions:

Thickness: The 0.75mm thickness indicates a light-duty metal angle, which is strong enough for general drywall and gypsum board installations, providing adequate reinforcement without adding excess weight.

Length: The 3600mm length is a standard size, which is approximately 12 feet. It is often chosen for larger wall or ceiling applications to minimize the number of joints and seams in the angle, providing a smooth finish over long spans.

Material:

Metal Angle: Typically, these are made from galvanized steel (coated with a protective layer of zinc to prevent rusting), but they can also be made from other metals like aluminum or stainless steel for specific applications. Galvanized steel is the most common due to its durability and corrosion resistance.

The zinc coating protects the angle from environmental factors, especially moisture, which is crucial in areas with high humidity or exposed to direct water sources.

Design:

The metal angle is typically L-shaped, forming a 90-degree angle, and is used for corner reinforcement or as a trim at the meeting point of walls and ceilings or drywall edges.

This type of angle is often used to give a clean and defined edge to drywall installations, preventing damage from impacts and ensuring a smooth finish for the wall corners.

Applications of the 0.75x3600mm Metal Angle Wall Angle:

Drywall and Gypsum Board Corner Reinforcement:

This metal angle is widely used for reinforcing the corners where drywall or gypsum board meets the wall or ceiling. It ensures that the corners stay sharp and undamaged over time.

It helps to prevent chipping, cracking, or abrasions to drywall, especially in high-traffic areas.

Wall-Ceiling Junctions:

The angle is used at the junctions where the ceiling meets the wall in drywall systems. It adds both strength and aesthetic appeal to the transition between surfaces.

It is also useful for finishing the edges of suspended ceilings, where the drywall edges need to be neatly defined.

Trim for Drywall Edges:

When finishing drywall or plasterboard installations, the metal angle is often used to protect the edges from damage while providing a finished look.

It also prevents moisture and dirt accumulation at the corners, which can weaken the drywall over time.

Interior and Exterior Applications:

Suitable for both interior and exterior drywall and gypsum board installations. If the angle is used outdoors or in humid areas, ensure the metal is weather-resistant (like galvanized steel) to prevent rust and deterioration.

Advantages of the 0.75x3600mm Metal Angle Wall Angle:

Corrosion Resistance:

The galvanized steel ensures that the angle resists rust and corrosion, making it suitable for use in areas with high humidity, like kitchens or bathrooms, or areas exposed to moisture.

Durability:

With a 0.75mm thickness, this metal angle provides sufficient strength to reinforce the corners and edges of drywall installations without being overly bulky. It ensures long-term protection from physical damage.

Neat, Clean Finish:

The L-shaped design creates a sharp, well-defined corner between the wall and ceiling or between walls, enhancing the visual appeal of drywall installations. The angle provides a professional finish to the drywall work.

Easy Installation:

The metal angle is simple to install and is typically fixed to the drywall edges using drywall screws, nails, or adhesives. Once secured, joint compound can be applied over the angle to achieve a smooth, seamless surface.

Cost-Effective:

Compared to other corner reinforcement materials, galvanized metal angles are often affordable and widely available, making them a cost-effective choice for drywall projects.

Installation Process:

Cutting the Angle:

Measure and cut the 3600mm metal angle to the desired length using metal snips or a hacksaw. This ensures the angle fits perfectly at the junction of the drywall.

Positioning:

Place the angle at the corner of the drywall where the wall meets the ceiling or two walls meet. Ensure that the angle fits snugly in the corner for an even, smooth finish.

Securing the Angle:

Use drywall screws or nails to secure the angle to the drywall. Ensure it is properly attached and aligned with the edge of the wall or ceiling to provide a neat finish.

It can be attached along the length of the angle, ensuring it sits flat against the drywall.

Applying Joint Compound:

Once the angle is secured, apply a thin layer of joint compound over the angle and smooth it out with a taping knife.

Allow the compound to dry and apply additional layers if necessary, sanding each layer to achieve a smooth surface.

Sanding and Painting:

After the joint compound has dried, sand the surface to remove any rough areas and achieve a smooth transition between the wall/ceiling and the corner bead.

Once sanded, you can paint the angle and drywall to match the rest of the room.

Conclusion:

The 0.75x3600mm metal angle wall angle is a crucial component in drywall and gypsum board installations, offering both structural reinforcement and aesthetic finishing. Made from galvanized steel, it provides corrosion resistance and durability, making it an ideal choice for high-humidity environments. With its simple installation process and cost-effectiveness, it provides an easy and efficient solution for reinforcing corners and edges in drywall projects. Whether used for interior or exterior applications, this metal angle ensures your drywall installations stay intact and visually appealing over time.

Selection Guide for Ceiling Channel Materials: A Comparison of Light Steel vs. Aluminum in Terms of L

In ceiling construction projects, ceiling channels serve as the critical framework supporting the ceiling surface layer, and their material selection directly impacts the project's quality and service life.

2025-07-06

Designing with Corner Wall Angles: Enhancing Room Aesthetics with Finishing Touches

Introduction In the world of interior design, even the smallest details can make a significant impact on the overall aesthetic of a room. One often overlooked area is the corner wall angles. These seemingly insignificant junctions between w

2025-07-03

Commercial-Grade Corner Wall Angles for Heavy-Duty Construction Projects

In heavy-duty construction projects such as industrial plants, large commercial complexes, and transportation hubs, corners are critical parts of the building structure that constantly face severe challenges. Frequent collisions from heavy equipment and e

2025-06-30

DIY Corner Wall Angle Finishing and Professional Results

In home decoration, DIY corner wall treatments have gained immense popularity among homeowners striving to elevate the quality of their living spaces. Corners are susceptible to damage and highly noticeable, so the way they are handled directly influences

2025-06-27