Ceiling Grid

Drywall partition

Ceiling channel

Corner Wall angle

Accessories

Steel profiles

Support customization

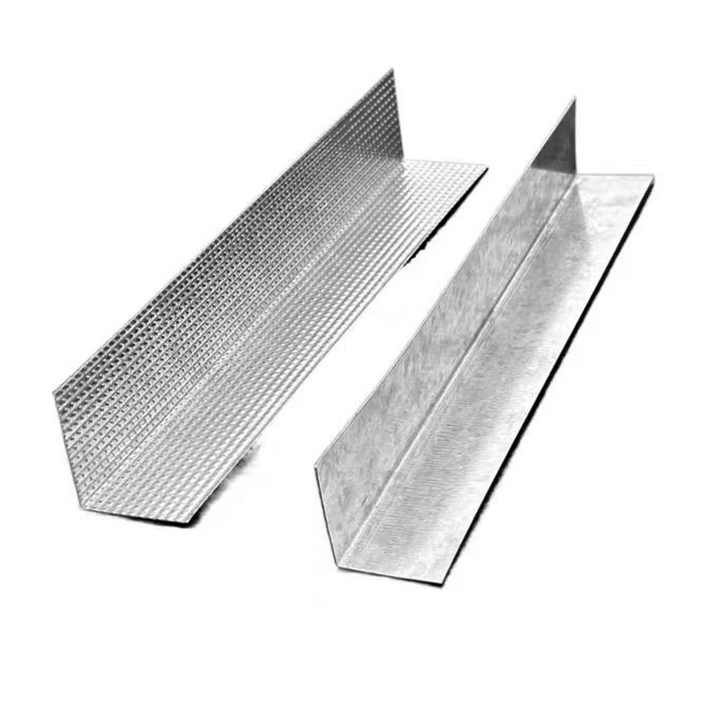

30mm suspended ceiling system iron angle wall angle

A 30mm suspended ceiling system iron angle wall angle is a type of metal angle used in suspended ceiling systems and drywall installations to create a clean and sturdy junction between the ceiling and walls. It is typically made from galvanized steel or iron, providing strength and durability for the ceiling framework, as well as helping to define and protect the edges of the ceiling.

Key Features of 30mm Suspended Ceiling System Iron Angle Wall Angle:

Material:

Galvanized Steel or Iron: The angle is commonly made from galvanized steel (coated with a layer of zinc for corrosion resistance) or iron, ensuring the angle has good durability and resistance to rust or corrosion, making it ideal for use in damp or humid environments such as bathrooms and kitchens.

The metal angle is typically coated to prevent rusting, enhancing its longevity.

Size:

The term "30mm" refers to the width of the angle, which is the dimension of the exposed surface once installed along the ceiling-to-wall junction. The other leg of the angle (height) may vary but is typically designed to be proportional to the 30mm width, providing stability and support for the ceiling grid.

The length of the angle can vary according to the needs of the project, typically available in standard lengths such as 2.4m (8ft) or 3m (10ft).

Design:

The angle is L-shaped, meaning it forms a 90-degree corner between the ceiling and the wall. This ensures that the edge of the suspended ceiling tiles or panels is secured and neatly finished, offering a professional and sharp-looking junction.

Perforations may be present in the angle to allow the joint compound to adhere better and help in attaching drywall or plaster to the wall or ceiling.

Finish:

The galvanized finish offers a silver-gray appearance, and the angle is often smooth, although some may have a textured surface or can be painted for aesthetic purposes.

Smooth finishes help with joint compound application, allowing for an even and clean surface when finishing the ceiling and wall junction.

Applications of 30mm Suspended Ceiling System Iron Angle Wall Angle:

Suspended Ceiling Systems:

The 30mm suspended ceiling angle is most commonly used in suspended ceiling systems to form the perimeter of the ceiling. It is installed at the edge of the ceiling, providing a straight, neat finish where the ceiling meets the wall.

It helps secure the main channels or cross tees of the ceiling grid, supporting the suspended ceiling panels (tiles) in place and ensuring the framework is aligned and stable.

Drywall and Plasterboard Walls:

In drywall or plasterboard installations, the 30mm wall angle helps to reinforce the ceiling edges and prevents the drywall corners from damage, ensuring they remain intact and well-protected.

It can be used to frame the edges of gypsum boards or drywall panels where they meet the ceiling, providing structural support and a neat, professional appearance.

Ceiling Perimeter Detailing:

Used as a perimeter detail in ceiling systems, the 30mm iron angle offers both structural support and visual appeal. It is essential for creating sharp, precise corners at the junctions between the ceiling and walls.

Ceiling Grid System:

The angle also forms part of the ceiling grid system, helping to secure and stabilize the suspended ceiling panels and tiles. It is crucial for the correct positioning of the grid system to ensure the ceiling tiles fit properly.

Partition Wall Systems:

The angle can also be used to frame the edges of partition walls made of drywall or gypsum board. It helps to ensure the edge of the wall meets the ceiling in a neat and secure manner.

Advantages of 30mm Suspended Ceiling System Iron Angle Wall Angle:

Corrosion Resistance:

Galvanized steel provides excellent corrosion resistance, making the angle highly durable and suitable for use in areas with high humidity, such as bathrooms, kitchens, and basements.

Durability:

The metal angle is strong and can withstand the physical stresses encountered in a ceiling system, protecting the drywall corners from damage and ensuring a solid ceiling structure.

Ease of Installation:

The L-shape design makes the angle easy to install along the ceiling edges. It can be securely fastened using nails, screws, or drywall staples.

The perforations in the angle assist in bonding with joint compound, ensuring a seamless finish.

Clean, Sharp Finish:

The 30mm angle provides a sharp, neat corner between the ceiling and the wall, which is important for creating a professional-looking interior. Once covered with joint compound, it helps form a smooth, crisp edge.

Versatility:

The 30mm iron angle can be used in both residential and commercial construction, providing a clean finish in offices, homes, schools, hospitals, and more.

Protects Drywall Edges:

The angle helps to protect the edges of drywall and plasterboard, which are vulnerable to chipping and damage from impacts or everyday wear and tear.

Aesthetic Appeal:

The zinc coating on the angle offers a clean, professional look, and the angle can be painted to match the room's décor, allowing it to blend seamlessly with the walls and ceiling.

Installation Process:

Measure and Cut:

First, measure the length needed for the 30mm ceiling angle at the perimeter where the ceiling meets the wall. Cut the angle to size using metal snips or a hack saw if needed.

Align and Position:

Position the angle along the ceiling-wall junction, ensuring that it fits snugly against both the wall and the ceiling. Ensure that the 30mm side is aligned properly to form a clean right-angle.

Secure the Angle:

Attach the angle to the wall and ceiling using drywall screws, nails, or staples. Make sure the angle is flush and level to create a straight and even line around the perimeter.

Apply Joint Compound:

Once the angle is secured, apply joint compound over the surface, covering the metal and blending it into the surrounding drywall. Use a taping knife to smooth the compound evenly.

Finishing:

After the joint compound has dried, sand it smooth and apply additional coats as needed. Once finished, the joint should look seamless and clean, blending well with the ceiling and wall.

Painting:

Optionally, you can paint the angle to match the ceiling and wall color for a unified, professional finish.

Conclusion:

A 30mm suspended ceiling system iron angle wall angle is a critical component in ceiling installation and drywall construction, offering strength, protection, and a clean, finished look at the junction between the ceiling and walls. Its corrosion-resistant galvanized steel construction ensures durability, while its easy installation process and aesthetic versatility make it an essential part of both residential and commercial ceiling systems.

The Advantages and Applications of Light Steel Keel: Why It Has Become the Preferred Material in Mode

In the modern construction industry, light steel keel has gradually become an indispensable building material. With its outstanding performance and diverse applications, light steel keel has become the material of choice for many building projects. So, wh

2025-03-08

Advantages and Applications of Drywall partitions: Easily Create Multifunctional Spaces

In modern architecture and interior design, efficient space division and utilization are key. Drywall partitions, with their unique advantages, have become the material of choice for an increasing number of construction and renovation projects. Whether in

2025-03-05

The Future of Light Steel Walls: Technological Innovation and Market Prospects

In the construction industry, light steel walls have gradually become an important choice in modern buildings due to their superior performance and environmentally friendly characteristics. With the continuous advancement of technology and changing market

2025-03-02

New Trends in Building Energy Efficiency: How Light Steel Walls Contribute to Green Environmental Pro

As global climate change and environmental issues become increasingly severe, energy efficiency and environmental protection have become critical topics in modern societal development. Whether it's controlling energy consumption or reducing greenhouse gas

2025-02-27