Troubleshooting Common Issues with Drywall Partitions

2024-11-09 14:12:54

Drywall partitions are widely used for their versatility and ease of installation, but like any construction material, they can encounter issues over time. Here’s a guide to troubleshooting some common problems with drywall partitions and tips on how to resolve them:

1. Cracks and Gaps in the Drywall

Cause: Cracks in drywall can occur due to settling of the building, thermal expansion and contraction, or poor installation techniques.

Solution: Small cracks can be repaired with joint compound or spackle, followed by sanding and painting. For larger cracks or gaps, apply a reinforcing tape or mesh over the crack before covering with compound. Ensure proper framing and joint support to avoid future cracking, especially in high-traffic or load-bearing areas.

Preventive Measure: Use high-quality joint tape and compound, and ensure proper expansion joints are included in high-stress areas.

2. Sagging Drywall

Cause: Drywall can sag over time due to the weight of the material or improper installation. This is especially common in ceilings or large, unsupported wall sections.

Solution: For minor sagging, tighten any loose fasteners or add extra drywall screws to reinforce the area. If sagging is severe, the affected drywall may need to be replaced with a stronger, more supportive material or reinforced with additional framing.

Preventive Measure: Ensure that ceiling drywall is properly supported by ceiling joists and that proper fastener spacing is followed during installation.

3. Moisture Damage and Mold Growth

Cause: Drywall is susceptible to moisture, which can lead to mold growth and weakening of the material. This problem is common in bathrooms, kitchens, or basements with poor ventilation.

Solution: If drywall has been exposed to significant moisture, it should be replaced entirely to prevent mold from spreading. Use moisture-resistant drywall or mold-resistant drywall in high-humidity areas to prevent future issues.

Preventive Measure: Install proper ventilation systems and use moisture-resistant drywall in wet areas. Regularly check for leaks and water damage to prevent mold growth.

4. Holes and Dents

Cause: Drywall can become dented or punctured due to accidental impacts or heavy objects being pushed against the wall.

Solution: Small holes can be filled with joint compound, while larger holes may require a patch or new section of drywall. After patching, sand the area smooth and repaint to match the surrounding wall.

Preventive Measure: Install corner protectors or use impact-resistant drywall in high-traffic areas to reduce the chance of dents or holes.

5. Visible Screw or Nail Heads

Cause: Nail or screw heads may become visible over time due to poor installation, movement in the wall, or settling of the building.

Solution: If nails or screws are protruding or causing visible bumps, remove the fasteners and replace them with drywall screws. Cover the screw heads with joint compound, sand smooth, and repaint the area.

Preventive Measure: Use screws instead of nails for better holding power, and make sure the fasteners are driven just below the surface of the drywall.

6. Warping or Bowing

Cause: Warping or bowing of drywall can occur due to high humidity, improper storage of drywall before installation, or the application of too much moisture during finishing.

Solution: If the drywall is warped, it may need to be replaced, especially if it affects structural integrity. For minor bowing, you can try to straighten the drywall by applying a layer of joint compound to one side and carefully pressing it back into shape. After the compound dries, sand and paint the surface.

Preventive Measure: Store drywall properly before installation, away from moisture and direct sunlight. Use moisture-resistant drywall in areas prone to high humidity.

7. Poor Finishing or Taping

Cause: Inadequate taping or finishing of drywall joints can result in visible seams, lumps, or a rough texture.

Solution: Reapply joint compound over the seams, re-smooth the surface, and allow it to dry completely before sanding. If necessary, apply additional layers of compound to fill in low spots and smooth out the surface. Finally, repaint to ensure a consistent finish.

Preventive Measure: Use high-quality joint tape and compound, and ensure all seams are properly aligned and sealed during installation. Proper finishing is essential for a smooth and durable drywall surface.

8. Sound Transmission Issues

Cause: Drywall can allow sound to travel between rooms, especially in multi-family dwellings or offices.

Solution: Use specialized soundproof drywall, which incorporates sound-dampening layers to reduce noise transmission. Alternatively, add insulation or mass-loaded vinyl between drywall layers to improve soundproofing.

Preventive Measure: Install soundproof drywall or acoustic insulation in areas where noise reduction is important, such as bedrooms, offices, or conference rooms.

9. Drywall Stains and Discoloration

Cause: Stains or discoloration can occur due to water damage, nicotine, or other environmental factors.

Solution: Clean stained areas with a mild detergent, and for more persistent stains, use a stain-blocking primer before repainting the surface. For water stains, check for leaks and repair the source of the moisture.

Preventive Measure: Use stain-resistant or mold-resistant drywall, and address any leaks or moisture issues promptly.

Conclusion

While drywall partitions are generally durable and reliable, common issues such as cracks, moisture damage, and sagging can occur over time. Regular maintenance, proper installation, and the use of suitable materials can help prevent many of these problems. When issues do arise, prompt attention and repair can restore drywall partitions to their original functionality and appearance.

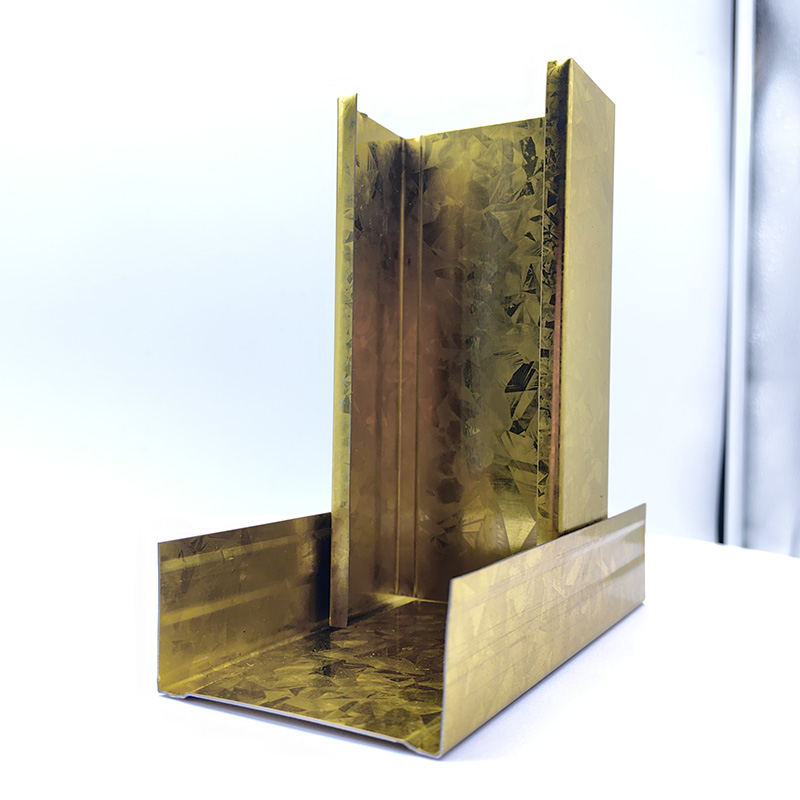

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

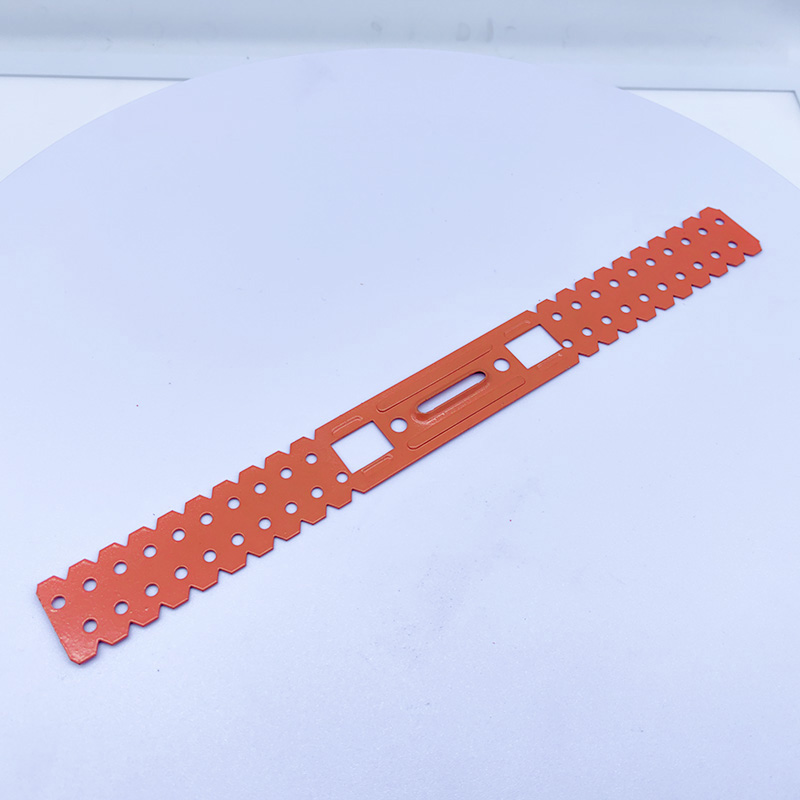

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

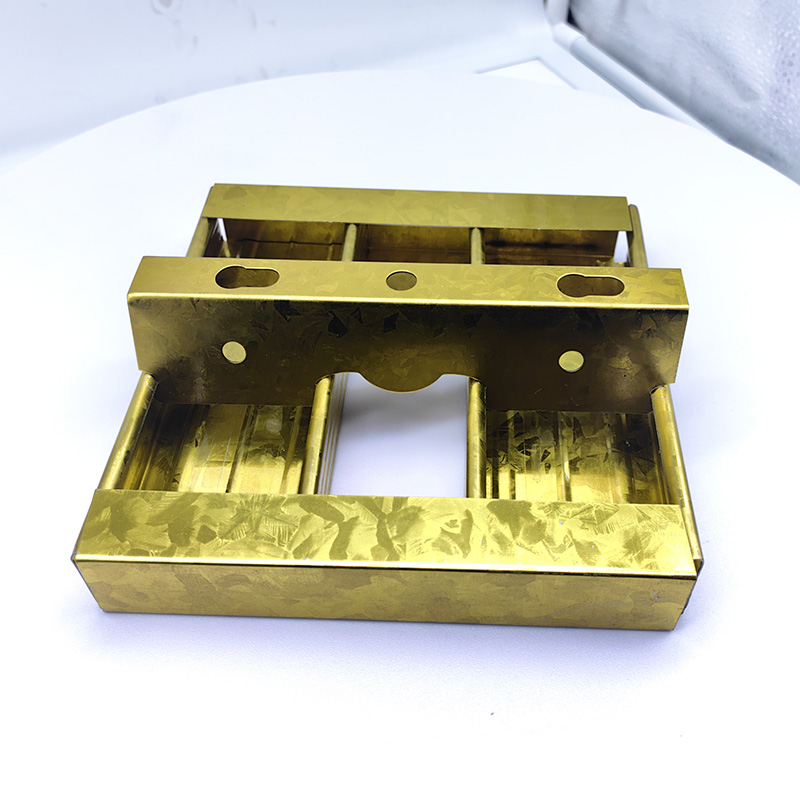

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

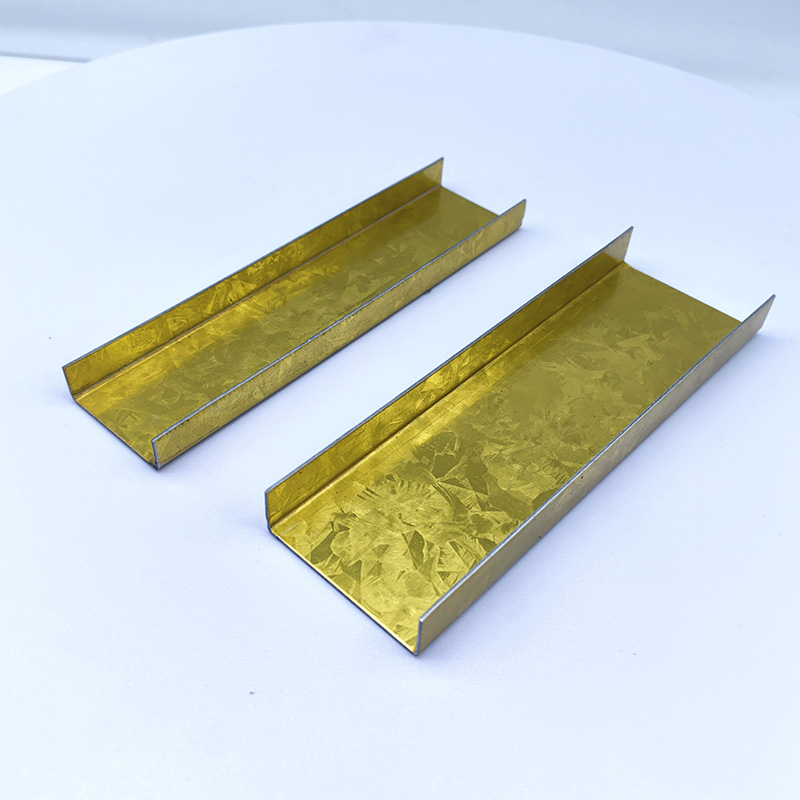

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...