Key Points for Plasterboard Partition Wall Construction to Ensure Project Quality

2025-04-26 05:38:08

In interior decoration projects, partition walls play a crucial role in dividing space functions, with their construction quality directly affecting user experience and spatial aesthetics. Thanks to advantages such as being lightweight, fire-resistant, soundproof, and easy to install, plasterboard partition walls have become a popular choice in modern renovations. However, overlooking critical points during the construction process can lead to issues like cracking, deformation, and soundproofing failure. This article systematically analyzes key points throughout the entire construction process of plasterboard partition walls to assist in creating high-quality partition wall projects.

I. Preparations Before Construction

Material Preparation: Select appropriate types of plasterboards based on different scenarios; choose light steel or wooden studs considering strength, moisture-proof, anti-corrosion properties, and cost-effectiveness; ensure auxiliary materials like self-tapping screws, sealants, and joint fillers meet requirements.

Tool Preparation: Equip tools including electric saws, drills, screwdrivers, levels, and straightedges, ensuring they are in good condition before use.

Site Preparation: Ensure the site is clean and level, accurately measure and mark out the position of partition walls using lines to guide subsequent construction.

II. Key Points for Stud Installation

Follow the principle of installing horizontal studs before vertical ones, fix them securely with expansion bolts or nails, monitor the installation process with a level to ensure alignment.

III. Key Points for Plasterboard Installation

Plan the layout of plasterboards according to wall dimensions, try to minimize joints, start fixing from one end or the middle towards both sides, ensure even spacing of screws, check flatness continuously during installation.

Handle board seams differently based on whether it's a flat seam or V-joint, apply filler and reinforcement tape accordingly to prevent future cracking.

IV. Detail Handling and Quality Inspection

Use special corner guards at internal and external corners, handle finishing neatly with sealant or decorative trim, accurately reserve openings for sockets and switches, repair any damages meticulously.

Conduct quality inspections against architectural decoration standards, measure indicators like flatness, verticality, squareness of corners, and joint width, ensure deviations are within specified limits.

V. Common Problems and Solutions

Address common problems like cracking, stud deformation, and poor sound insulation through careful material selection, precise construction techniques, and structural reinforcement measures.

VI. Conclusion

Construction of plasterboard partition walls requires meticulous attention from material selection, stud installation, board fixation, to detail handling, strictly adhering to construction norms and guidelines. Only by valuing every step can potential quality risks be effectively avoided, leading to sturdy, functional, aesthetically pleasing, and durable partition wall projects that solidly support spatial quality.

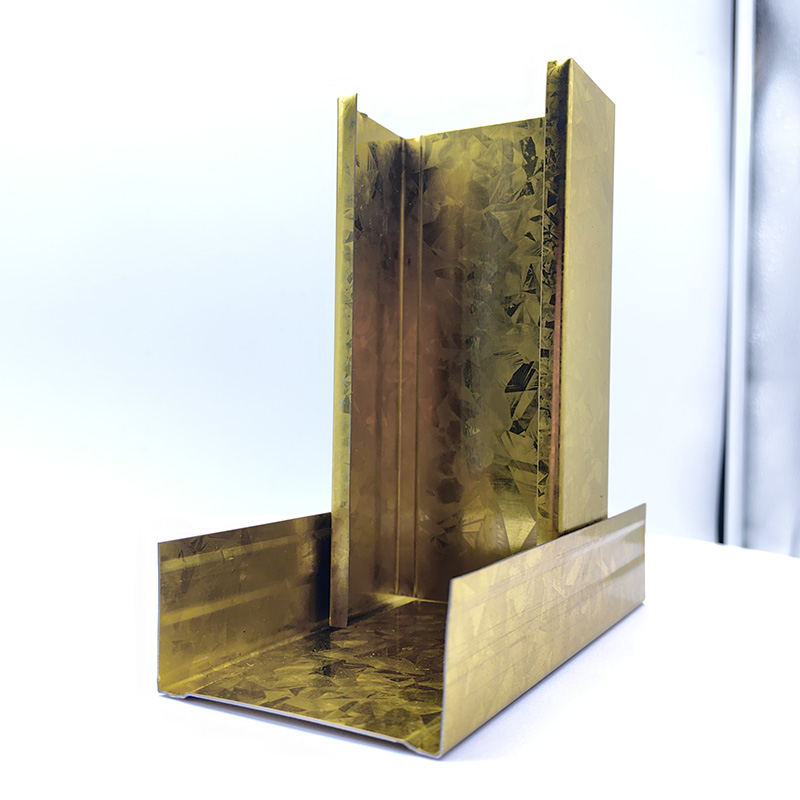

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

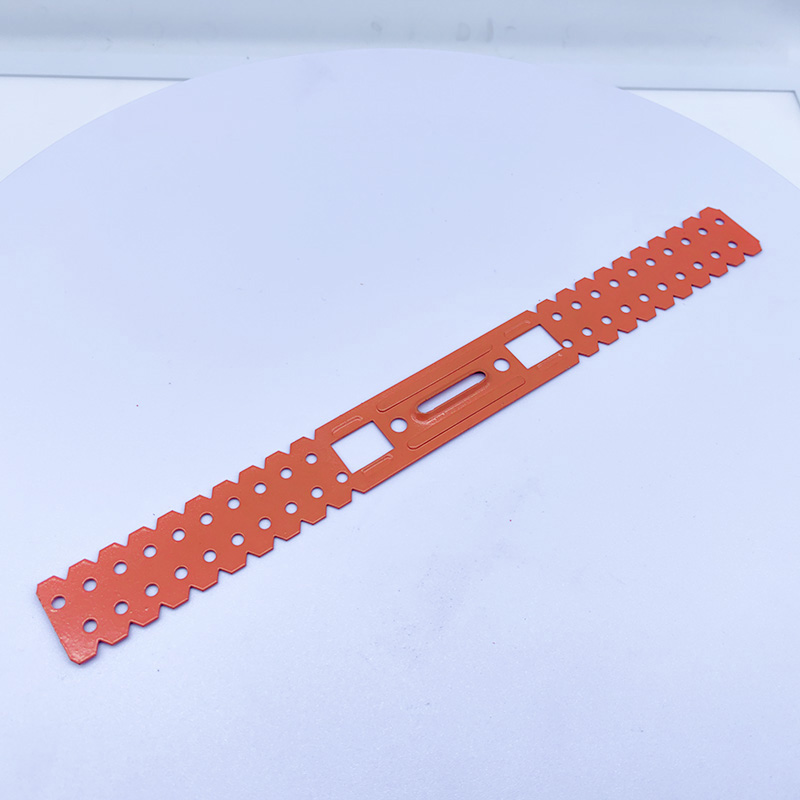

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

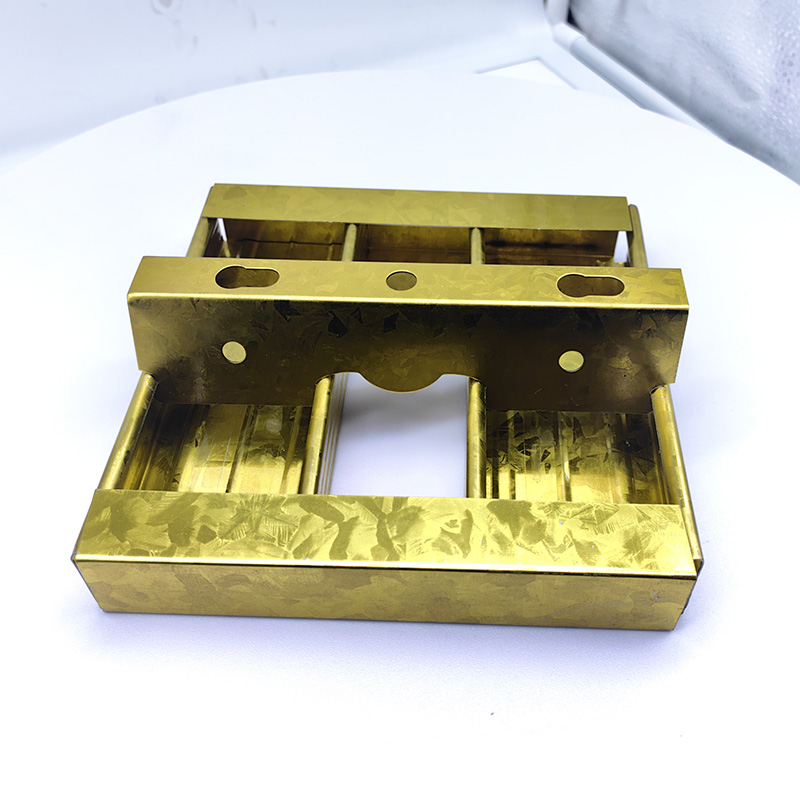

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

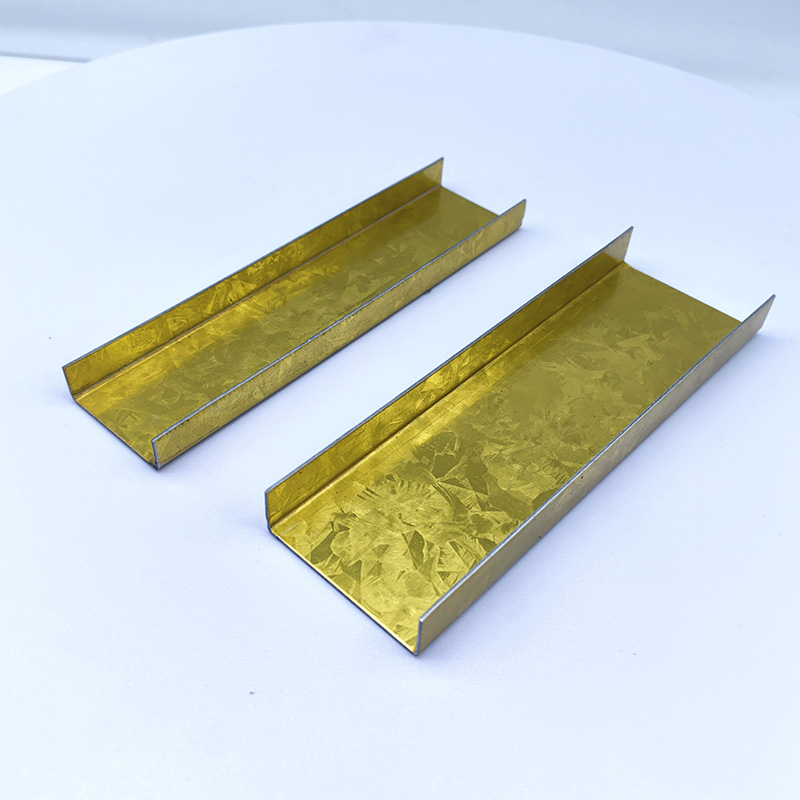

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...