Ceiling Grid

Drywall partition

Ceiling channel

Corner Wall angle

Accessories

Steel profiles

Support customization

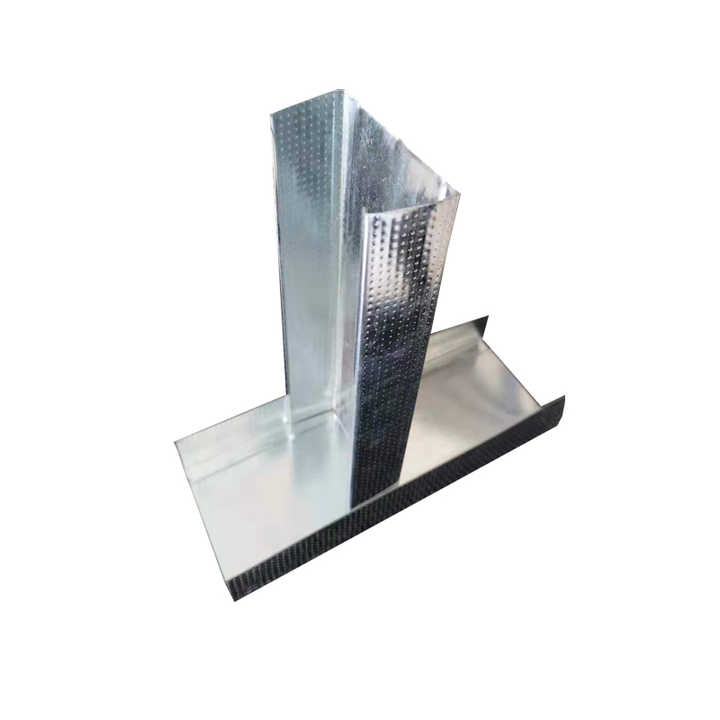

Hot dipped galvanized steel Metal Stud

Hot-Dipped Galvanized Steel Metal Studs are an essential component of modern construction, widely used for framing drywall partitions, ceilings, and walls. The term "hot-dipped galvanized" refers to a process in which steel is coated with a layer of zinc by dipping it into a molten zinc bath. This coating provides significant protection against rust and corrosion, ensuring the studs remain durable and reliable, especially in environments prone to moisture.

Key Features of Hot-Dipped Galvanized Steel Metal Studs:

Galvanization Process:

Hot-Dipped Galvanization involves immersing steel in a molten zinc bath, forming a thick, durable coating that protects the metal from oxidation and corrosion. This process significantly enhances the corrosion resistance of the steel, making it ideal for use in high-humidity areas, coastal regions, or any location where rust could be a concern.

Material Strength:

Steel is inherently strong, making it an excellent material for structural applications. Hot-dipped galvanized steel retains all the benefits of steel’s strength, including its ability to bear loads, provide structural integrity, and resist deformation.

The galvanized coating ensures that the steel does not degrade over time, which is especially important in structural framing where stability is critical.

Size and Shape:

Metal Studs come in various sizes and profiles depending on the application. The most common profile is C-shaped (similar to a C-channel) but they can also come in other shapes such as U-shape, Z-shape, or hat channels.

The size of the studs can vary, but typical widths range from 50mm to 100mm with thicknesses ranging from 0.3mm to 1.5mm. The thickness of the studs is selected based on the application’s load requirements and the type of construction being done.

Corrosion Resistance:

The zinc coating provides a barrier between the steel and the environment, which protects the material from rust and corrosion caused by moisture. This makes hot-dipped galvanized steel ideal for use in buildings that require long-term durability in environments like kitchens, bathrooms, and exterior walls, where exposure to moisture and humidity is more common.

Fire Resistance:

Steel is a non-combustible material, making it an excellent choice for fire-resistant construction. Hot-dipped galvanized steel maintains its fire-resistant properties, contributing to the overall fire rating of the ceiling or partition systems.

Lightweight:

Despite its strength and durability, galvanized steel metal studs are relatively lightweight compared to traditional wooden studs. This makes them easier to handle, transport, and install, leading to reduced labor and installation costs.

Environmental Resistance:

Hot-dipped galvanized steel is resistant to a variety of environmental conditions, including moisture, salt, chemicals, and pollutants. It is ideal for use in both indoor and outdoor applications and in corrosive environments such as near oceans, in industrial settings, or in buildings subject to heavy humidity.

Aesthetic Compatibility:

Metal studs, particularly galvanized ones, can provide a cleaner, more modern aesthetic compared to traditional wooden framing, making them suitable for buildings with exposed ceiling or partition systems.

Applications of Hot-Dipped Galvanized Steel Metal Studs:

Drywall Framing:

Hot-dipped galvanized steel metal studs are used extensively in the construction of drywall systems, such as partitions, ceilings, and false walls. These studs serve as the framework to which drywall panels are attached, providing stability and support.

Suspended Ceilings:

Metal studs are commonly used in suspended or dropped ceiling systems, where the studs are mounted to the ceiling grid, and the gypsum boards or ceiling tiles are attached to the framing system.

Interior Partition Walls:

These studs form the internal structural framework for partition walls between rooms in residential, commercial, and industrial buildings. They offer a stable structure for attaching drywall, insulation, or other wall finishes.

Acoustic and Fire-Rated Walls:

Due to their soundproofing capabilities and fire-resistant properties, galvanized steel metal studs are often used in the construction of acoustic or fire-rated partitions.

Exterior Framing:

In areas prone to harsh weather conditions or high moisture levels, hot-dipped galvanized metal studs are ideal for exterior framing applications, including exterior walls and roofing systems.

Ceiling Grid Systems:

Used to support gypsum ceiling tiles, acoustic tiles, or suspended ceilings, galvanized metal studs provide the necessary framework to ensure stability and structural integrity.

Advantages of Hot-Dipped Galvanized Steel Metal Studs:

Superior Durability:

The hot-dipped galvanization process protects the steel from corrosion, enhancing the lifespan of the studs and the overall structure.

Improved Structural Integrity:

These studs provide a sturdy framework that does not warp, twist, or shrink like wood, offering superior structural integrity for drywall and ceiling systems.

Reduced Maintenance:

The galvanized coating means the studs will not rust, reducing the need for maintenance and repairs. This makes them especially useful in areas where moisture and humidity are concerns.

Lightweight and Easy to Handle:

Compared to traditional wooden framing, galvanized steel metal studs are much lighter, which reduces installation time and labor costs.

Cost-Effective in the Long Run:

Although galvanized steel metal studs can be more expensive upfront than wood, their durability and resilience result in long-term savings by reducing the need for repairs and replacements over time.

Fire Safety:

Since steel is non-combustible, galvanized steel metal studs help improve the fire safety of the building, which is a critical consideration in building codes for commercial and industrial structures.

Eco-Friendly:

Steel is highly recyclable, and using galvanized steel reduces the environmental impact compared to other building materials like treated wood.

Installation of Hot-Dipped Galvanized Steel Metal Studs:

Preparation:

Before installing, measure and mark the layout for the stud framing system, ensuring the studs are positioned at correct intervals (typically 400mm or 600mm apart).

Mounting the Tracks:

Install top and bottom tracks (UD tracks) along the perimeter of the ceiling or floor. These tracks serve as the base for the vertical studs and are typically attached to the ceiling or floor using screws or fasteners.

Placing the Metal Studs:

Insert the vertical studs into the top and bottom tracks, ensuring they are spaced evenly. Use screws or clips to secure the studs to the tracks.

Attaching the Gypsum Board:

Once the framework is complete, attach the gypsum boards to the metal studs using drywall screws. Ensure that the boards are flush with the studs for a secure fit.

Finishing:

After the gypsum board is installed, apply joint compound over the seams, sand the surface smooth, and apply paint or other finishes as required.

Conclusion:

Hot-dipped galvanized steel metal studs are an excellent choice for building durable, fire-resistant, and corrosion-resistant drywall ceiling systems and partitions. The galvanization process provides long-lasting protection against rust and moisture, making them ideal for both indoor and outdoor applications. These studs provide a strong, lightweight, and cost-effective framing solution for modern construction, offering superior performance and longevity compared to traditional wood framing.

The Advantages and Applications of Light Steel Keel: Why It Has Become the Preferred Material in Mode

In the modern construction industry, light steel keel has gradually become an indispensable building material. With its outstanding performance and diverse applications, light steel keel has become the material of choice for many building projects. So, wh

2025-03-08

Advantages and Applications of Drywall partitions: Easily Create Multifunctional Spaces

In modern architecture and interior design, efficient space division and utilization are key. Drywall partitions, with their unique advantages, have become the material of choice for an increasing number of construction and renovation projects. Whether in

2025-03-05

The Future of Light Steel Walls: Technological Innovation and Market Prospects

In the construction industry, light steel walls have gradually become an important choice in modern buildings due to their superior performance and environmentally friendly characteristics. With the continuous advancement of technology and changing market

2025-03-02

New Trends in Building Energy Efficiency: How Light Steel Walls Contribute to Green Environmental Pro

As global climate change and environmental issues become increasingly severe, energy efficiency and environmental protection have become critical topics in modern societal development. Whether it's controlling energy consumption or reducing greenhouse gas

2025-02-27