Ceiling Grid

Drywall partition

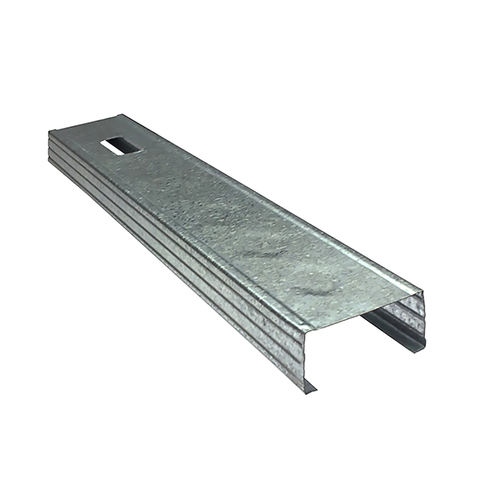

Ceiling channel

Corner Wall angle

Accessories

Steel profiles

Support customization

metal stud framing construction

Metal Stud Framing Construction is a method of building walls, partitions, and ceilings using metal studs and tracks as the primary structural framework. This technique is widely used in commercial, residential, and industrial construction because of its durability, strength, and resistance to various environmental factors. Here's a comprehensive look at metal stud framing construction:

Key Components of Metal Stud Framing:

Metal Studs:

Material: Metal studs are made of steel, typically galvanized to provide corrosion resistance. The steel is often coated with zinc (hot-dipped galvanization), which makes it resistant to rust, ideal for both interior and exterior construction.

Types: Metal studs come in different shapes and sizes, with the C-shaped and U-shaped profiles being the most common.

Sizes: Standard metal studs range in size from 50mm to 100mm in width and thicknesses from 0.3mm to 0.6mm. The spacing between studs is typically 16 inches (400mm) or 24 inches (600mm).

Purpose: Metal studs act as the vertical framing members that provide support for drywall, insulation, and other materials.

Metal Tracks:

Material: Like studs, tracks are also made from galvanized steel to ensure durability and corrosion resistance.

Purpose: Tracks are used as the horizontal framing members that sit at the top and bottom of the wall. They provide support for the vertical studs and allow for attachment to the ceiling and floor or the building's structure.

Sizes: Tracks are available in various widths, generally from 38mm to 64mm, and depths to match the specific needs of the project.

Drywall (Gypsum Board):

Material: Drywall is the most common material attached to the metal studs to form interior walls and ceilings. It is made of a layer of gypsum sandwiched between two layers of paper.

Standard Sizes: Drywall sheets are typically 4 feet x 8 feet (1.2m x 2.4m), though larger sheets can be used in some cases.

Screws and Fasteners:

Drywall Screws: These screws are used to attach drywall to the metal studs. They are typically self-tapping to facilitate easy installation.

Track Fasteners: Screws or anchors are used to secure the metal tracks to the floor and ceiling.

Insulation (Optional):

Acoustic Insulation: Metal stud framing is often paired with insulation materials like fiberglass, mineral wool, or foam board to provide soundproofing, thermal resistance, or both.

Resilient Channels (Optional):

Purpose: Resilient channels are used in some systems to reduce sound transmission. They are mounted between the drywall and the studs to create a decoupling effect, minimizing noise transfer.

Advantages of Metal Stud Framing:

Strength and Durability:

Metal studs provide a strong, rigid framework for walls and ceilings. They do not warp, twist, or bow like wooden studs, making them highly durable over time.

Corrosion Resistance:

Galvanized steel studs and tracks are resistant to rust and corrosion, making them suitable for environments with high moisture or humidity, such as bathrooms, kitchens, or areas near the coast.

Fire Resistance:

Steel is non-combustible, making metal stud framing an ideal choice for fire-rated partitions. This is especially important in commercial buildings, high-rise structures, and other fire-sensitive environments.

Lightweight:

Despite its strength, metal stud framing is lighter than traditional wood framing, making it easier to handle, transport, and install, which can lower labor costs.

Pest Resistance:

Metal framing is immune to pests such as termites, rodents, and mold, which can be issues in wood-framed buildings.

Eco-Friendly:

Steel is 90% recyclable, making it an environmentally friendly option that reduces waste in construction.

Precision and Uniformity:

Metal studs are manufactured to consistent dimensions, ensuring that the framing is straight and square, which reduces errors during construction.

Versatility:

Metal stud framing can be used for partition walls, ceiling grids, and exterior walls, and is compatible with a wide range of finishes, including drywall, plaster, or cement boards.

Applications of Metal Stud Framing:

Interior Partition Walls:

Non-load-bearing walls can be easily constructed using metal stud framing. These walls are common in offices, schools, hospitals, and apartments.

Ceiling Systems:

Metal stud framing is often used for suspended ceiling systems, where the tracks and studs create the framework for hanging ceiling tiles or gypsum boards.

Exterior Walls:

In some cases, metal stud framing can be used for exterior walls, especially when the structure needs to be resistant to environmental factors like moisture, temperature changes, or termites.

Soundproofing:

Metal stud framing is frequently used in environments that require soundproofing, such as home theaters, recording studios, or office buildings. Acoustic insulation and resilient channels can be used alongside the metal studs to enhance sound isolation.

Fire-Rated Partitions:

Fire-rated walls constructed using metal studs are essential in multi-story buildings and commercial spaces. The steel frame, combined with fire-resistant drywall, helps to meet fire code requirements.

Cladding Systems:

Metal stud framing is also used in cladding systems for facades or exterior applications when combined with materials like cement board or metal panels.

Installation Process of Metal Stud Framing:

Mark and Measure:

Start by marking the layout for the studs and tracks on the floor and ceiling. Use a level to ensure that the lines are straight and aligned.

Install Tracks:

Secure the metal tracks to the floor and ceiling, ensuring they are parallel and spaced correctly. Tracks are typically fastened using screws or anchors.

Insert and Secure Studs:

Insert the metal studs into the tracks and ensure they are spaced according to the project requirements (usually 16” or 24” apart). The studs are fastened into place using screws or clip fasteners.

Install Drywall:

Once the frame is in place, attach drywall sheets to the studs using drywall screws. The sheets should be secured at regular intervals to prevent sagging.

Finishing:

After the drywall is installed, the seams are covered with joint compound to smooth out any gaps or imperfections. Once dry, sand the compound and apply paint or other finishing treatments.

Price Range for Metal Stud Framing:

Metal Studs: Typically cost between $2 to $6 per meter, depending on the gauge and size.

Metal Tracks: Prices for tracks generally range from $1.50 to $4 per meter.

Drywall Sheets: Usually cost between $8 to $15 per sheet, depending on the thickness and type of drywall.

Drywall Screws: Cost around $10 to $20 per box (for approximately 1000 screws).

Conclusion:

Metal stud framing construction is a highly durable, efficient, and cost-effective method for building interior walls, ceilings, and non-load-bearing partitions. With galvanized steel studs and tracks, this framing system provides superior strength, fire resistance, and protection against moisture, pests, and environmental damage. It's lightweight, easy to install, and suitable for a wide range of applications, including commercial, residential, and industrial construction. Its eco-friendly, long-lasting nature makes it a preferred choice in modern construction projects.

Selection Guide for Ceiling Channel Materials: A Comparison of Light Steel vs. Aluminum in Terms of L

In ceiling construction projects, ceiling channels serve as the critical framework supporting the ceiling surface layer, and their material selection directly impacts the project's quality and service life.

2025-07-06

Designing with Corner Wall Angles: Enhancing Room Aesthetics with Finishing Touches

Introduction In the world of interior design, even the smallest details can make a significant impact on the overall aesthetic of a room. One often overlooked area is the corner wall angles. These seemingly insignificant junctions between w

2025-07-03

Commercial-Grade Corner Wall Angles for Heavy-Duty Construction Projects

In heavy-duty construction projects such as industrial plants, large commercial complexes, and transportation hubs, corners are critical parts of the building structure that constantly face severe challenges. Frequent collisions from heavy equipment and e

2025-06-30

DIY Corner Wall Angle Finishing and Professional Results

In home decoration, DIY corner wall treatments have gained immense popularity among homeowners striving to elevate the quality of their living spaces. Corners are susceptible to damage and highly noticeable, so the way they are handled directly influences

2025-06-27