5 Key Factors to Consider When Choosing Corner Angles for Walls

2024-11-09 11:01:05

In the fields of construction and manufacturing, corner angles for walls are an essential material for connections and support. Their selection and use are crucial. The correct corner angle not only improves the stability and load-bearing capacity of the building structure but also effectively prevents wall cracks and deformation, enhancing overall aesthetics. When choosing corner angles, the following five key factors should not be overlooked.

1.Application Scenario and Requirements

Different application scenarios require different attributes from corner angles, such as strength and corrosion resistance. For example, corner angles used in building structures need to have high strength and stability, while corner angles used in mechanical manufacturing may focus more on wear resistance and impact resistance. Therefore, when selecting a corner angle, it is essential to first define the specific application and requirements to ensure the chosen angle meets actual needs.

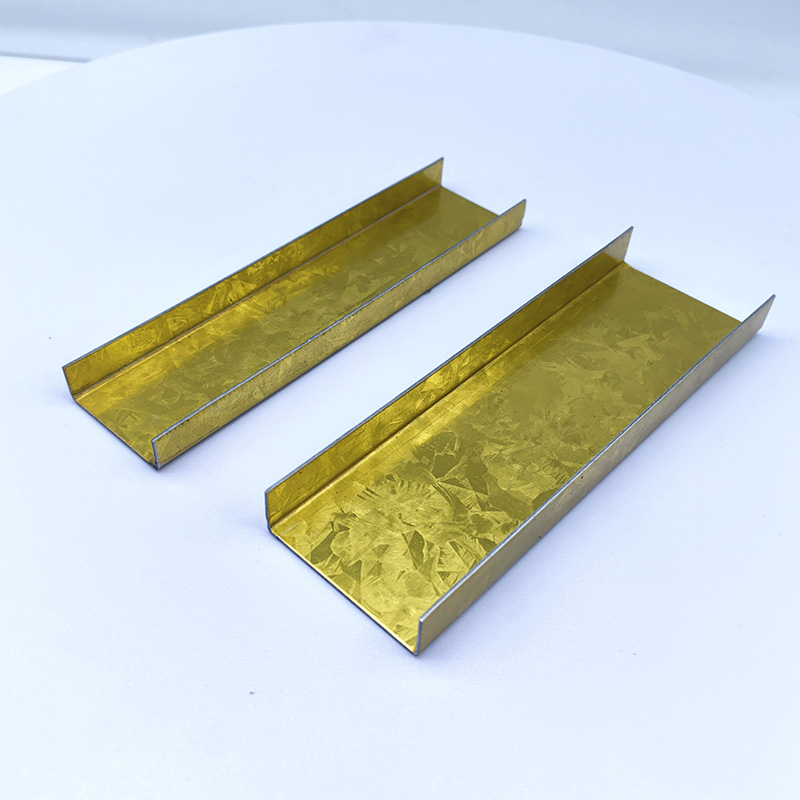

2.Dimensions and Precision

The size and specifications of the corner angle directly affect its performance. When selecting, it is necessary to measure the actual wall corner dimensions to ensure that the length, thickness, and height of the corner angle match. A size that is too large or too small can lead to unnecessary waste or affect installation effectiveness. Additionally, size precision is a critical factor affecting the quality of the corner angle. It is important to choose products that meet actual needs to ensure accuracy and stability during installation and use.

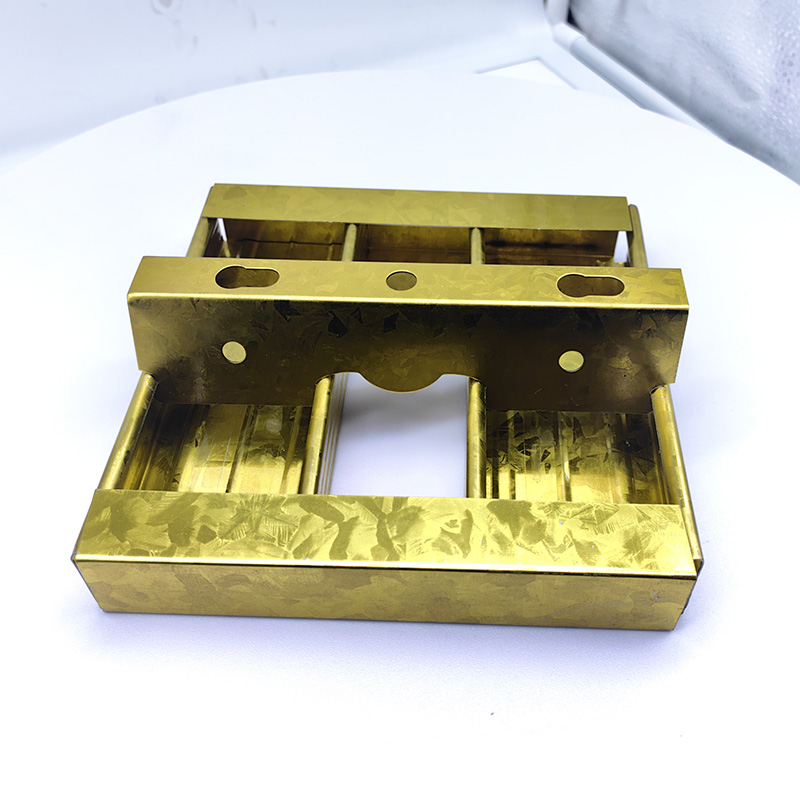

3.Material and Performance

The material and performance of the corner angle are directly related to its service life and load-bearing capacity. Common materials for corner angles include Q235, Q345, etc. Different materials have different mechanical properties and corrosion resistance. When selecting, the appropriate material and performance indicators, such as yield strength, tensile strength, and compressive strength, should be chosen based on actual needs. These indicators reflect the strength and load-bearing capacity of the corner angle and are crucial to ensuring structural safety.

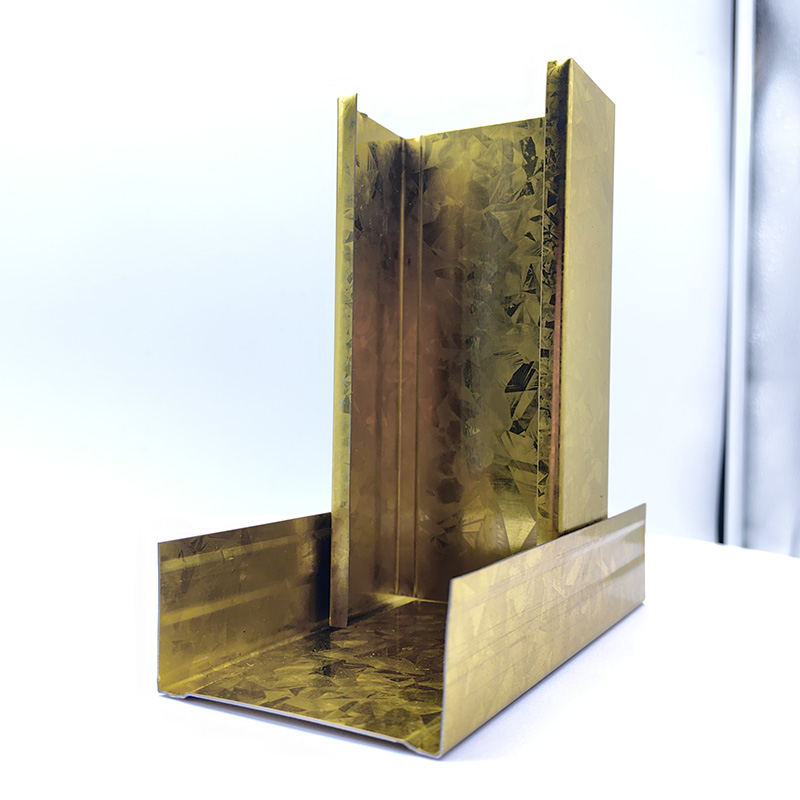

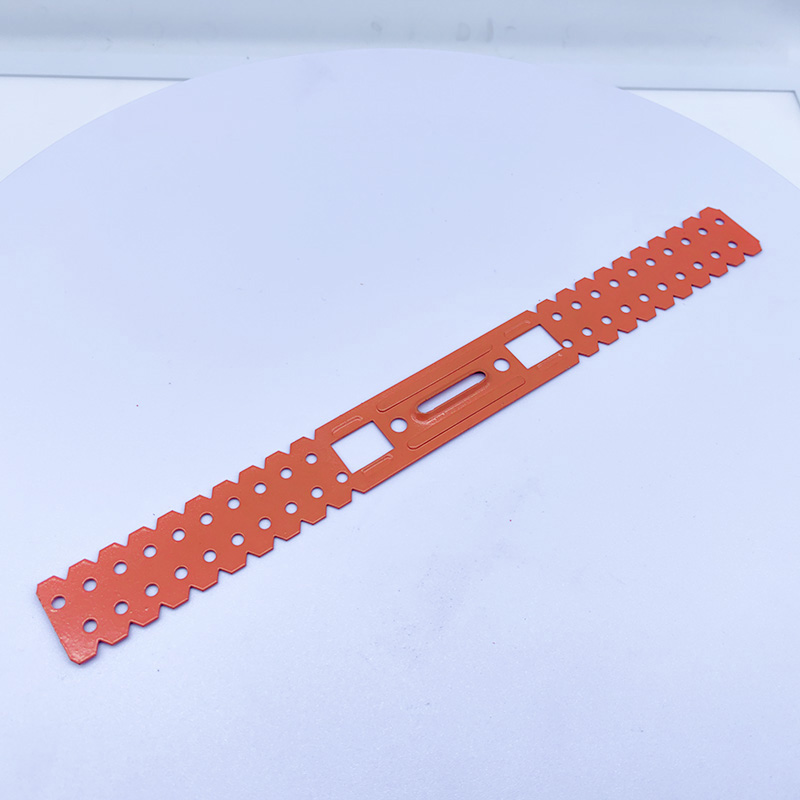

4.Surface Quality and Appearance

Surface quality also affects the service life and load-bearing capacity of the corner angle. A high-quality corner angle should have a smooth, flat surface without bubbles, cracks, or other defects. The surface quality can be observed to determine the level of the corner angle’s quality. Additionally, the cross-sectional shape of the corner angle should be considered. Equal-leg angles are suitable for situations that require symmetry, while unequal-leg angles are suitable for situations with asymmetric requirements.

5.Price and Supplier Reputation

Price is an important factor when selecting corner angles. When choosing, the raw material price, market supply-demand relationship, processing costs, and transportation costs should all be considered to choose a product with a good price-performance ratio. At the same time, the supplier’s reputation and reputation should not be ignored. Choosing a reputable and well-regarded brand or manufacturer ensures the quality of the purchased corner angles and after-sales service, reducing risks during use.

In summary, when selecting corner angles for walls, attention should be paid to the application scenario and requirements, dimensions and precision, material and performance, surface quality and appearance, and price and supplier reputation. By considering these factors comprehensively, it ensures that the chosen corner angles meet practical needs and have good performance, providing strong support for the successful progress of construction and manufacturing projects.

A Double Anti-Rust Gold Partition Wall Stud is a type of steel stud commonly used in the co...

A CD UD Profile Furring Clip U Clamp is a type of metal fastening component used in the ins...

A 60mm Ceiling Grid refers to a type of suspended ceiling system, commonly used in commerci...

38mm Main Tee and 50mm Main Tee refer to the widths of the main tee profiles used in suspen...