In the construction and renovation industry, corner angle steel is an essential structural material widely used in wall reinforcement, decorative trim, and building frameworks. However, as corner angle steel is often exposed to various complex environments, its corrosion resistance becomes a key factor in determining its service life and safety. This article will provide a detailed introduction to the corrosion protection methods of corner angle steel and its suitability for different environments, helping you make better choices when selecting and using angle steel materials.

1. Corrosion Protection Methods for Corner Angle Steel

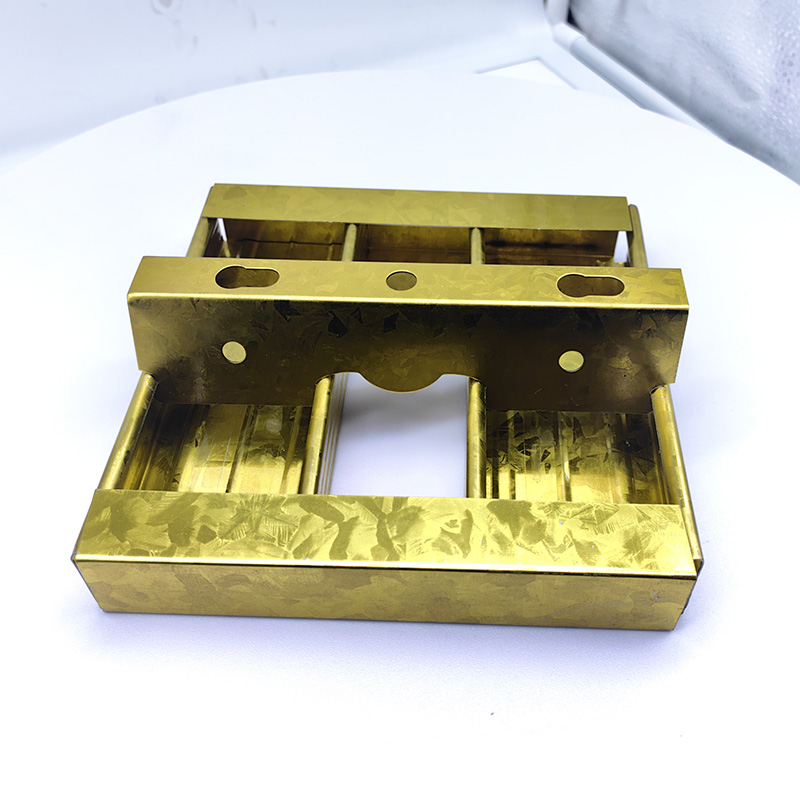

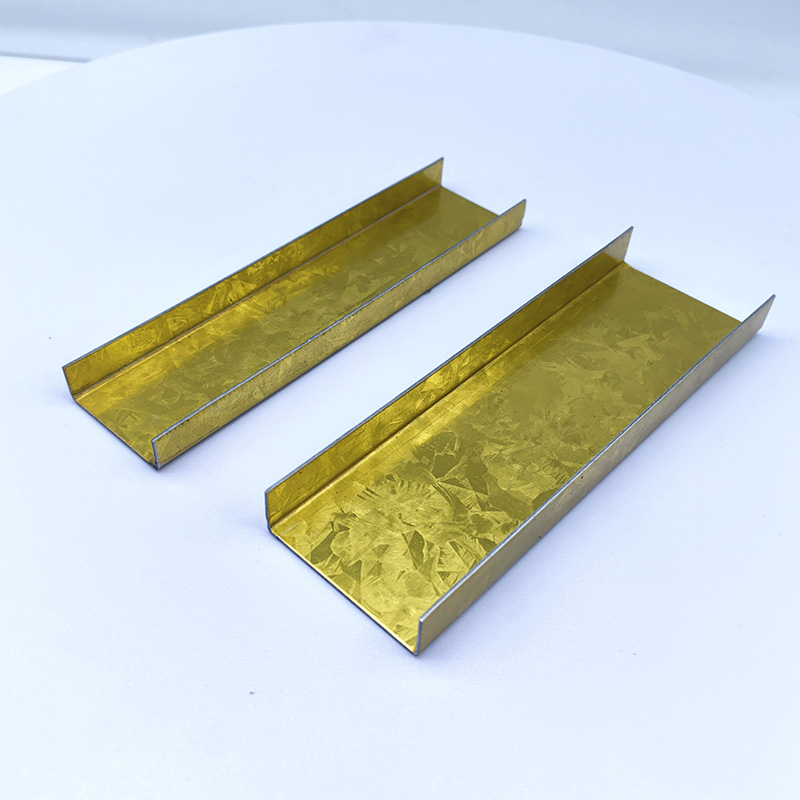

1.1 Hot-Dip Galvanizing

Hot-dip galvanizing is one of the most common corrosion protection methods. The angle steel is immersed in molten zinc, where a metallurgical reaction occurs between the zinc and the steel surface, forming a dense zinc-iron alloy layer. This alloy layer has excellent corrosion resistance, effectively protecting the steel from atmospheric corrosion, water corrosion, and soil corrosion. Hot-dip galvanized angle steel performs exceptionally well in outdoor, humid, or corrosive environments, making it widely used in bridges, power towers, building facades, and other applications.

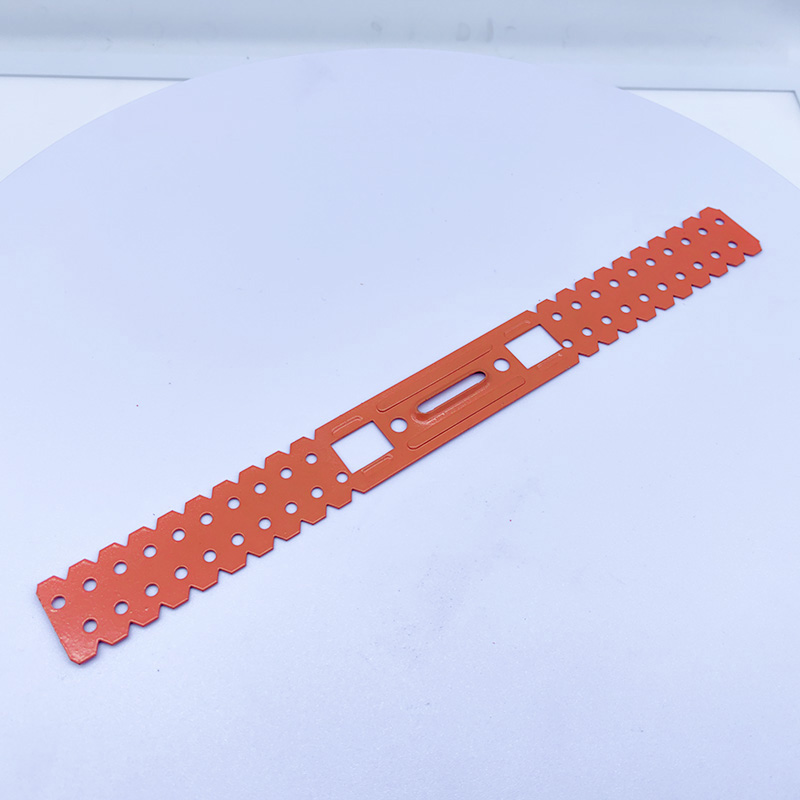

1.2 Spray Painting

Spray painting is another common corrosion protection method. Depending on requirements, various types of coatings can be used, such as epoxy resin, polyurethane, or fluorocarbon paint, all of which offer excellent weather resistance, corrosion resistance, and decorative properties. Spray painting not only protects angle steel from corrosion but also enhances its aesthetic appeal. This method is suitable for indoor decorations, interior partitions, and similar environments.

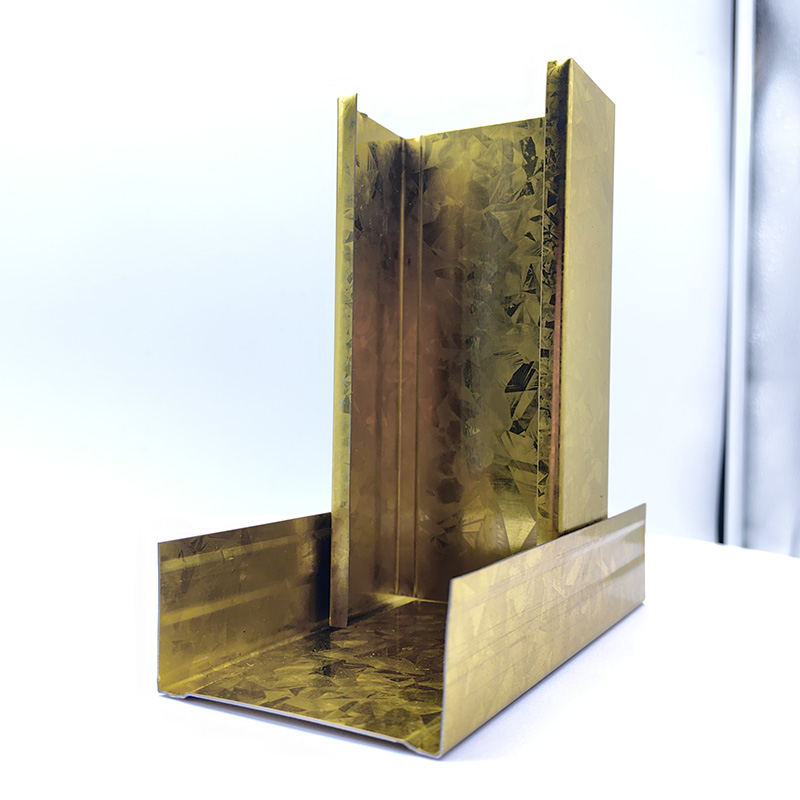

1.3 Electroplating

Electroplating involves using an electrochemical process to deposit a metal coating, such as chromium, nickel, or copper, onto the surface of the angle steel to improve its corrosion resistance. The electroplated layer provides good gloss and decorative properties while offering effective protection against corrosion. Electroplated angle steel is commonly used in interior decorations and furniture manufacturing.

1.4 Thermal Spraying

Thermal spraying techniques, including flame spraying, arc spraying, and plasma spraying, involve spraying molten metals or non-metallic materials onto the surface of angle steel to form a continuous protective layer. Thermal spraying creates thicker coatings with superior corrosion resistance, making it ideal for extremely corrosive environments such as chemical processing and marine engineering.

2. Application Environments of Corner Angle Steel

2.1 Indoor Environments

In indoor environments such as offices and residences, corner angle steel is mainly used for decorative trim and wall reinforcement. Since indoor environments are relatively dry and mild, the corrosion protection requirements are lower. Therefore, angle steel with spray painting or electroplating treatments can effectively meet corrosion protection needs while enhancing the visual appeal.

2.2 Outdoor Environments

Outdoor environments are complex and ever-changing, with exposure to rain, wind, ultraviolet rays, and other factors that demand high corrosion resistance from corner angle steel. Hot-dip galvanized angle steel, due to its excellent corrosion resistance, is the preferred choice for outdoor applications. Whether it is for building facades, bridges, power towers, or other outdoor structures, hot-dip galvanized angle steel provides long-lasting and reliable protection.

2.3 Corrosive Environments

In highly corrosive environments, such as chemical plants and marine engineering, corner angle steel faces even more severe challenges. These environments often contain strong acids, alkalis, and saltwater, all of which demand exceptional corrosion protection. Thermal sprayed angle steel, with its thick protective coating, is the best choice for these harsh environments.

2.4 Humid Environments

Humid environments, such as basements and bathrooms, are prone to corrosion of angle steel. In such cases, hot-dip galvanized angle steel performs exceptionally well, providing effective protection against moisture-induced corrosion. Additionally, choosing moisture-resistant coatings for spray painting is also a good option.

Conclusion

The corrosion protection and environmental suitability of corner angle steel are crucial to ensuring the material's service life and safety. By understanding the advantages and disadvantages of different corrosion protection methods and the suitability of angle steel for various environments, you can select the appropriate angle steel material based on your specific needs. This will enhance the quality and durability of your construction and renovation projects. We hope this article helps you gain a better understanding of the corrosion protection of corner angle steel and its applicable environments, providing valuable guidance for your material selection.