Ceiling Grid

Drywall partition

Ceiling channel

Corner Wall angle

Accessories

Steel profiles

Support customization

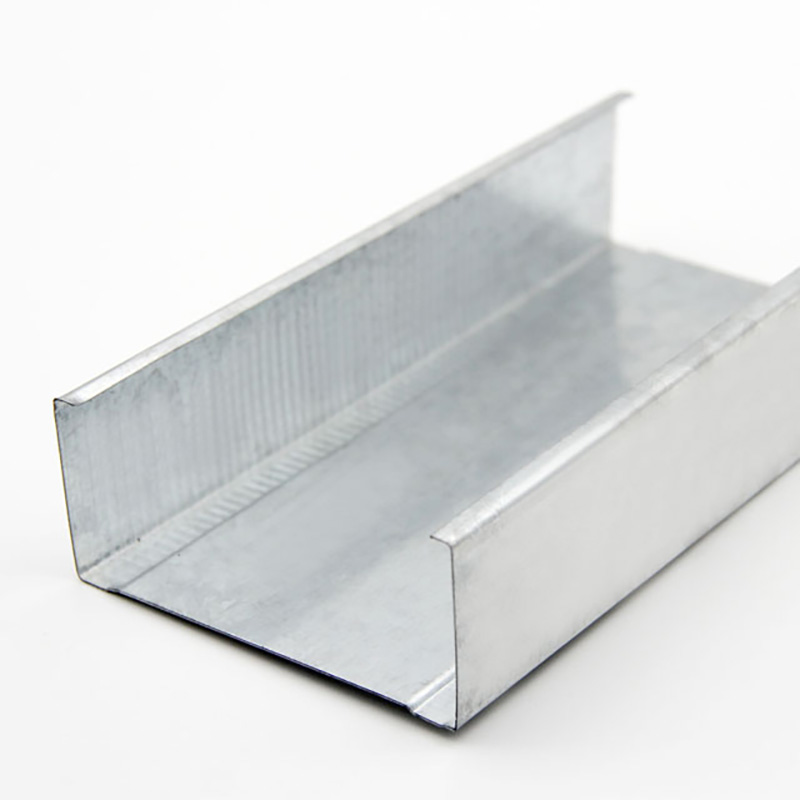

100mm Vertical Stud

A 100mm Vertical Stud is a framing component used in the construction of drywall partitions and ceiling systems. The 100mm refers to the width or flange size of the stud, typically measured across the profile from one edge to the other. Vertical studs form the backbone of the wall frame, providing structural support for drywall, gypsum boards, or other wall finishes. These studs are part of a steel framing system and are commonly made from galvanized steel to ensure strength and corrosion resistance.

Key Features and Benefits of a 100mm Vertical Stud:

Size and Dimensions:

The 100mm measurement refers to the width of the stud's flanges (the horizontal edges of the stud). The depth or thickness of the stud can vary, but it is typically designed to match the wall or ceiling system requirements.

The height (length) of the stud is typically in 2.4 meters or 3 meters, but custom lengths can be manufactured.

The thickness of the stud's steel may range from 0.4mm to 1.5mm, depending on the structural requirements of the wall or ceiling system.

Material:

Galvanized steel is the most common material used for these studs. It is treated with a zinc coating to protect it from corrosion and rust, making it ideal for environments with higher moisture levels (such as bathrooms or kitchens) and enhancing its longevity.

Strength and Load-Bearing Capacity:

A 100mm vertical stud offers a stronger and more rigid frame compared to smaller studs (like 50mm or 75mm) because of its wider profile.

These studs can support the weight of drywall or gypsum board and are especially useful in fire-rated walls, acoustic systems, or high-traffic areas where the wall may need to bear more load.

Applications:

Drywall Partitions: The 100mm stud is commonly used in interior partition walls, providing a stable structure for drywall or gypsum board panels.

Ceiling Systems: These studs are also used in ceiling framing systems, where they support ceiling tiles or gypsum boards.

Fire-Rated Walls: Due to the non-combustible nature of steel, 100mm vertical studs are used in fire-rated wall systems to create walls that meet fire safety standards.

Acoustic Partitions: These studs can be used in soundproof walls to create barriers that reduce noise transmission between rooms or spaces.

Corrosion Resistance:

The galvanized steel ensures the 100mm vertical stud is resistant to rust, making it suitable for areas with high moisture or humidity, like bathrooms, kitchens, and basements.

Easy Installation:

These studs are typically installed by inserting them into the top and bottom tracks (horizontal framing components), with the studs spaced at regular intervals, usually 400mm or 600mm apart.

After the studs are installed, drywall is attached to the vertical studs with drywall screws.

Fire Resistance:

Steel studs are non-combustible, providing fire resistance to the overall wall or ceiling system. When combined with fire-rated gypsum board, these studs contribute to fire-rated partition systems that help slow the spread of fire in buildings.

Installation Process:

Track Installation:

Begin by securing the top and bottom tracks to the floor and ceiling. These tracks provide the horizontal frame that the vertical studs will be inserted into.

Stud Placement:

Place the 100mm vertical studs into the tracks, ensuring that they are aligned vertically and spaced at the correct intervals (typically 400mm or 600mm apart). Use screws or clips to secure the studs in place.

Drywall Attachment:

Once the stud framework is in place, attach the drywall or gypsum board to the studs using drywall screws. Make sure the drywall is securely fastened to the studs at regular intervals.

Finishing:

After the drywall is installed, cover the seams with joint compound (mud), smooth the surface, and sand it down to create a smooth finish. The wall is then ready for painting or other finishing materials.

Applications of 100mm Vertical Studs:

Interior Drywall Partitions:

These studs are ideal for creating interior walls between rooms or spaces. The 100mm width provides additional strength to support heavier drywall panels or allow for more insulation.

Fire-Rated Walls:

100mm vertical studs are commonly used in fire-rated walls. The combination of the steel studs and fire-resistant gypsum boards meets stringent fire safety requirements, making them suitable for commercial, industrial, and residential buildings.

Acoustic Walls:

For applications requiring soundproofing, these studs allow the installation of insulation or acoustic materials between the studs, reducing sound transmission between rooms or spaces.

Heavy-Duty Applications:

These studs are ideal for high-load applications, where the wall system might need to support additional weight, such as heavy fixtures, shelving, or wall-mounted equipment.

Moisture-Prone Areas:

100mm vertical studs are suitable for bathrooms, kitchens, or basements, where moisture levels can be high. The galvanized steel protects the stud from corrosion in such environments.

Conclusion:

The 100mm vertical stud is a versatile and essential component in drywall partition systems, offering additional strength and support compared to smaller studs. Made from galvanized steel, these studs provide resistance to corrosion and are ideal for fire-rated, acoustic, and heavy-duty applications. They are used in both residential and commercial projects to create stable walls and ceilings that support drywall, gypsum board, and other finishes. Their strength, fire resistance, and corrosion resistance make them a reliable choice for modern construction projects.

The Advantages and Applications of Light Steel Keel: Why It Has Become the Preferred Material in Mode

In the modern construction industry, light steel keel has gradually become an indispensable building material. With its outstanding performance and diverse applications, light steel keel has become the material of choice for many building projects. So, wh

2025-03-08

Advantages and Applications of Drywall partitions: Easily Create Multifunctional Spaces

In modern architecture and interior design, efficient space division and utilization are key. Drywall partitions, with their unique advantages, have become the material of choice for an increasing number of construction and renovation projects. Whether in

2025-03-05

The Future of Light Steel Walls: Technological Innovation and Market Prospects

In the construction industry, light steel walls have gradually become an important choice in modern buildings due to their superior performance and environmentally friendly characteristics. With the continuous advancement of technology and changing market

2025-03-02

New Trends in Building Energy Efficiency: How Light Steel Walls Contribute to Green Environmental Pro

As global climate change and environmental issues become increasingly severe, energy efficiency and environmental protection have become critical topics in modern societal development. Whether it's controlling energy consumption or reducing greenhouse gas

2025-02-27