Ceiling Grid

Drywall partition

Ceiling channel

Corner Wall angle

Accessories

Steel profiles

Support customization

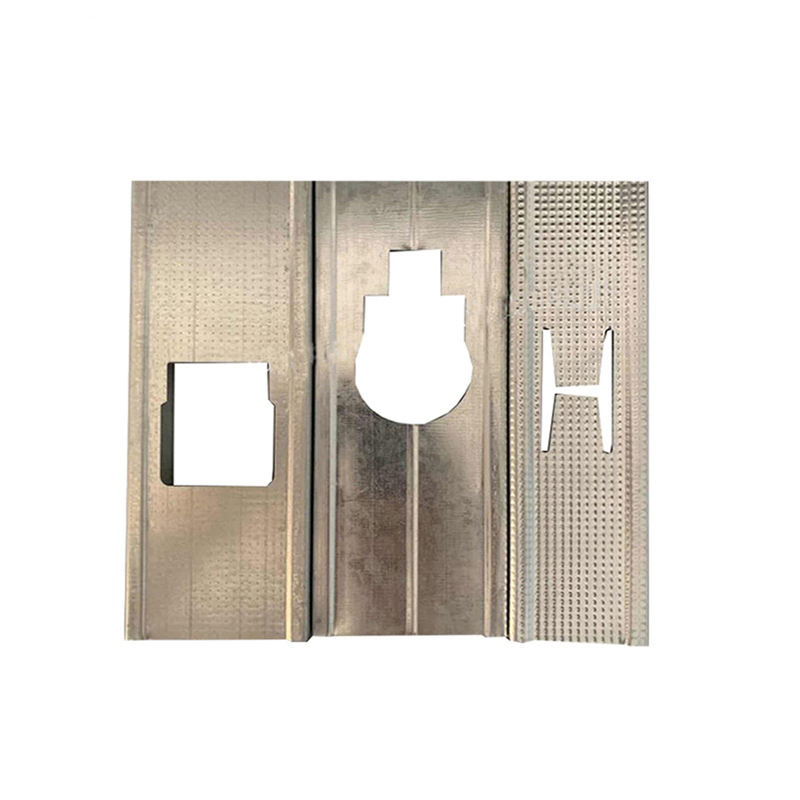

hot dipped galvanized steel drywall stud

A hot-dipped galvanized steel drywall stud is a type of framing component used in the construction of drywall partitions, ceilings, and other structural systems. These studs are made from steel that has been coated with a layer of zinc through a hot-dipped galvanization process, offering enhanced protection against rust and corrosion. Galvanized steel studs are widely used in both residential and commercial construction for their strength, durability, and long-lasting performance.

Key Features of Hot-Dipped Galvanized Steel Drywall Studs:

Hot-Dipped Galvanization:

The steel studs are coated with a zinc layer by submerging them in molten zinc. This process creates a durable, corrosion-resistant coating that protects the studs from rust and oxidation.

The galvanized finish makes these studs particularly suited for environments with high moisture levels, such as bathrooms, kitchens, or coastal areas where exposure to humidity and salt is common.

Corrosion Resistance:

The zinc coating helps prevent rust and corrosion, extending the lifespan of the drywall framing system. This makes galvanized steel studs ideal for areas where moisture exposure is high, preventing the studs from deteriorating over time.

Strength and Durability:

Steel studs are stronger and more rigid than traditional wood framing, offering superior load-bearing capacity. This makes them suitable for structural framing, supporting heavy drywall panels without warping or bowing.

The galvanized coating does not compromise the strength of the steel; rather, it protects it from external elements that could cause damage.

Lightweight:

Galvanized steel studs are lighter than wood studs, making them easier to handle and install. This can lead to savings in labor costs and installation time, while still providing a strong and stable framework for drywall or gypsum board.

Fire Resistance:

Steel is inherently non-combustible, making it a great choice for fire-resistant partition systems. Galvanized steel studs help improve the fire safety of drywall partitions and contribute to the overall fire rating of the walls or ceilings.

Non-Warping:

Unlike wood studs, steel studs will not warp, shrink, or expand due to changes in temperature or humidity. This ensures a straight, stable framework for drywall panels, even in fluctuating environmental conditions.

Eco-Friendly:

Steel is highly recyclable and can be reused, making galvanized steel drywall studs a more sustainable building material compared to other options like wood or plastic.

Aesthetic Compatibility:

Galvanized steel studs can be used in visible or exposed framing applications, where the clean, industrial look of steel complements modern architectural designs.

Applications of Hot-Dipped Galvanized Steel Drywall Studs:

Interior Drywall Partitions:

Hot-dipped galvanized steel studs are primarily used to frame interior drywall partitions in both residential and commercial buildings. They provide a stable and durable structure for drywall boards or gypsum panels.

Suspended Ceiling Systems:

These studs are used in suspended ceiling systems, providing the framework to hold gypsum boards, acoustic tiles, or other ceiling materials.

Fire-Rated Walls:

Galvanized steel studs are often used in the construction of fire-rated walls and fire-resistant partitions due to their ability to withstand high temperatures without compromising the structural integrity of the wall.

Exterior Framing:

Although typically used for interior framing, galvanized steel studs are also suitable for exterior framing in areas where the studs are exposed to moisture or harsh environmental conditions.

Acoustic or Soundproof Walls:

Steel studs, when combined with the right materials (e.g., soundproof drywall or insulation), can contribute to acoustic or soundproof walls, as steel naturally helps block sound transmission.

Moisture-Prone Areas:

Bathrooms, kitchens, and basements benefit from the corrosion-resistant nature of galvanized steel studs, making them a preferred choice for framing in moisture-prone areas.

Installation Process:

Track Installation:

Top and bottom tracks (UD tracks) are first installed along the floor and ceiling. The tracks serve as the horizontal framework to hold the vertical studs in place.

Stud Placement:

The vertical studs are inserted into the UD tracks, spaced at regular intervals (typically 400mm or 600mm apart). The studs should be aligned and plumb to ensure the partition is straight and stable.

Attachment of Drywall:

Once the studs are secured, the drywall panels or gypsum boards are attached to the studs using drywall screws. The panels are fixed to the studs, and the screws should be spaced properly to avoid damaging the board or compromising its hold.

Finishing:

After the drywall is secured to the studs, the seams between the panels are covered with joint compound, then smoothed and sanded to create a seamless surface ready for painting or other finishes.

Conclusion:

Hot-dipped galvanized steel drywall studs are an essential material for constructing drywall partitions, ceilings, and fire-rated walls. The galvanization process ensures superior corrosion resistance, making them suitable for use in environments prone to moisture, humidity, or corrosive conditions. With their strength, lightweight nature, and fire resistance, galvanized steel studs provide a durable and cost-effective framing solution for modern construction projects.

The Advantages and Applications of Light Steel Keel: Why It Has Become the Preferred Material in Mode

In the modern construction industry, light steel keel has gradually become an indispensable building material. With its outstanding performance and diverse applications, light steel keel has become the material of choice for many building projects. So, wh

2025-03-08

Advantages and Applications of Drywall partitions: Easily Create Multifunctional Spaces

In modern architecture and interior design, efficient space division and utilization are key. Drywall partitions, with their unique advantages, have become the material of choice for an increasing number of construction and renovation projects. Whether in

2025-03-05

The Future of Light Steel Walls: Technological Innovation and Market Prospects

In the construction industry, light steel walls have gradually become an important choice in modern buildings due to their superior performance and environmentally friendly characteristics. With the continuous advancement of technology and changing market

2025-03-02

New Trends in Building Energy Efficiency: How Light Steel Walls Contribute to Green Environmental Pro

As global climate change and environmental issues become increasingly severe, energy efficiency and environmental protection have become critical topics in modern societal development. Whether it's controlling energy consumption or reducing greenhouse gas

2025-02-27